Looking to Reduce Machine Tool Setup Time? Read This.

ELK GROVE VILLAGE, IL, March 07, 2022 -

Time is money.

This is why so many shops find themselves looking to reduce their machine tool setup time. When the machine is not running, it’s not making money- a simple fact.

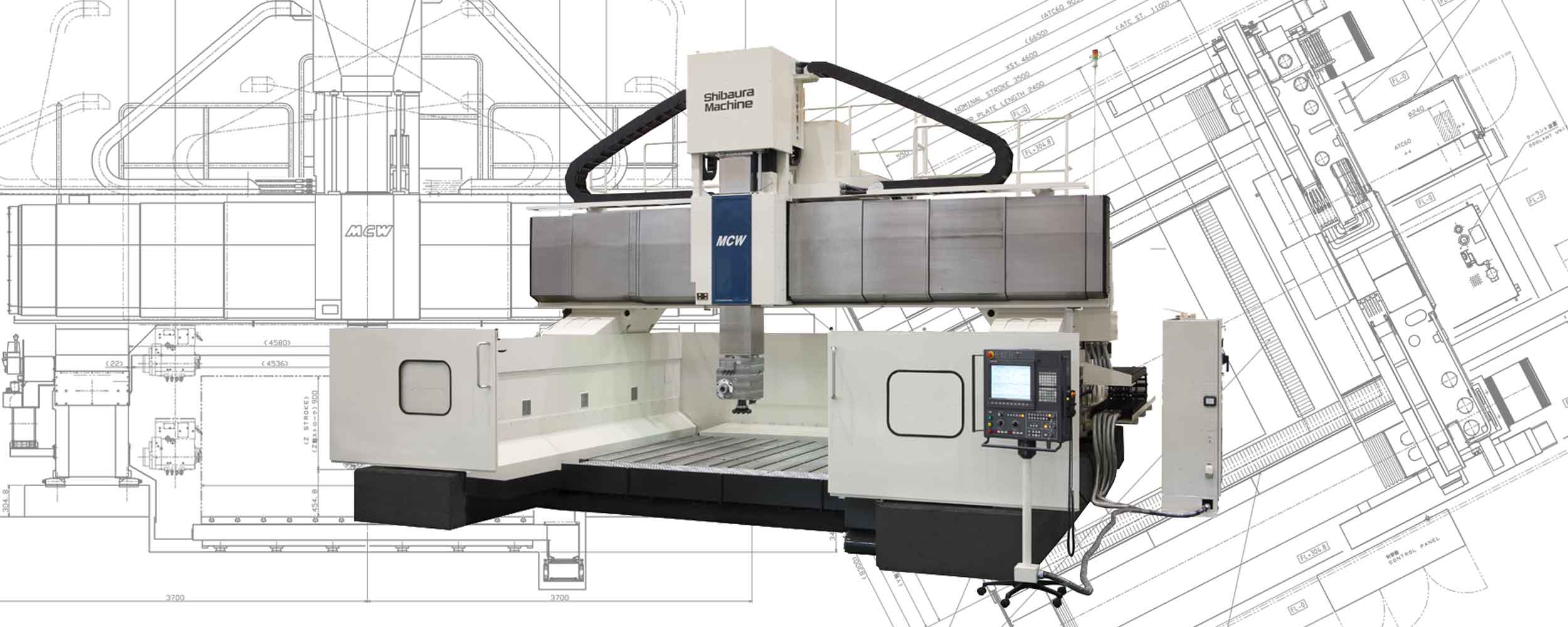

In order to maximize machine tool efficiency and accuracy an increase in setup automation options have been introduced over the years. This allows shops to increase throughput from their existing machinery, reduce errors, and place machinists on more proactive tasks. Shibaura Machine is highlighting five of the most popular ways to reduce machine tool setup time and increase productivity.

PALLET CHANGER

The addition of an automatic pallet changer offers a quick, precise, often low-cost part changing system that enables increased productivity. With an automatic pallet changer the operator is able to set up the next workpiece during the current workpieces machining operation delivering part-to-part change overs with repeatability and speed.

TOOL CHANGER

When you think about how many tool changes your machine tool will make during its lifetime, being able to minimize that time can make a big impact. All Shibaura Machine’s machine tools include automated tool changers so the operator no longer needs to manually perform this task, allowing for a further reduction in machine tool setup time.

QUICK-CHANGE TOOLING BLOCK

The quick-change tooling block systems on Shibaura Machine’s entire RAM style of vertical turning lathes (VTL’s) will considerably improve your workpiece throughput by reducing the number of setups, helping to increase machine tool return on investment.

WORKPIECE PROBING

Utilizing a workpiece probe during machining operations delivers improvements in workpiece quality and a reduction in errors from manual input. This automation also allows operators to focus on proactive engineering roles, bringing cost savings and significant quality improvements for all applications.

TOOL VERIFICATION SYSTEMS

With automated tool verification systems you can monitor cutting tool diameter and length offsets in a short period of time. This not only reduces setup time, but ensures correct tool parameters and that the machine is capable of the tolerances before any machining operations are carried out.

Start Saving Time

Certain tasks like tool setting and workpiece measuring will never go away and are critical to your machining operation. However, being able to automate these and other setup tasks can bring significant time and cost savings, while also improving repeatability and workpiece quality.

Contact the Machine Tool Team to learn more about the options available to help with setup time reduction.

Related Articles View All Machine Tools Articles

High Accuracy or Surface Finish Requirements? You Don’t Have to Choose.

ELK GROVE VILLAGE, IL, March 01, 2022 - Speeding up cycle times and part production is something shops have been in hot pursuit of for years. However, this isn’t the only way to impact profitability. Shops also need to be able to ensure that they are able ...

Read moreImprove Part Program Usability with the TOSNUC 999 Macro Programming Function

ELK GROVE VILLAGE, IL, February 22, 2022 - Macro programming for CNC machining provides shops countless benefits. It offers both power and flexibility, allowing machinists to implement improvements in just about every facet of a CNC environment. Many shops...

Read moreOptimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 - Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor ...

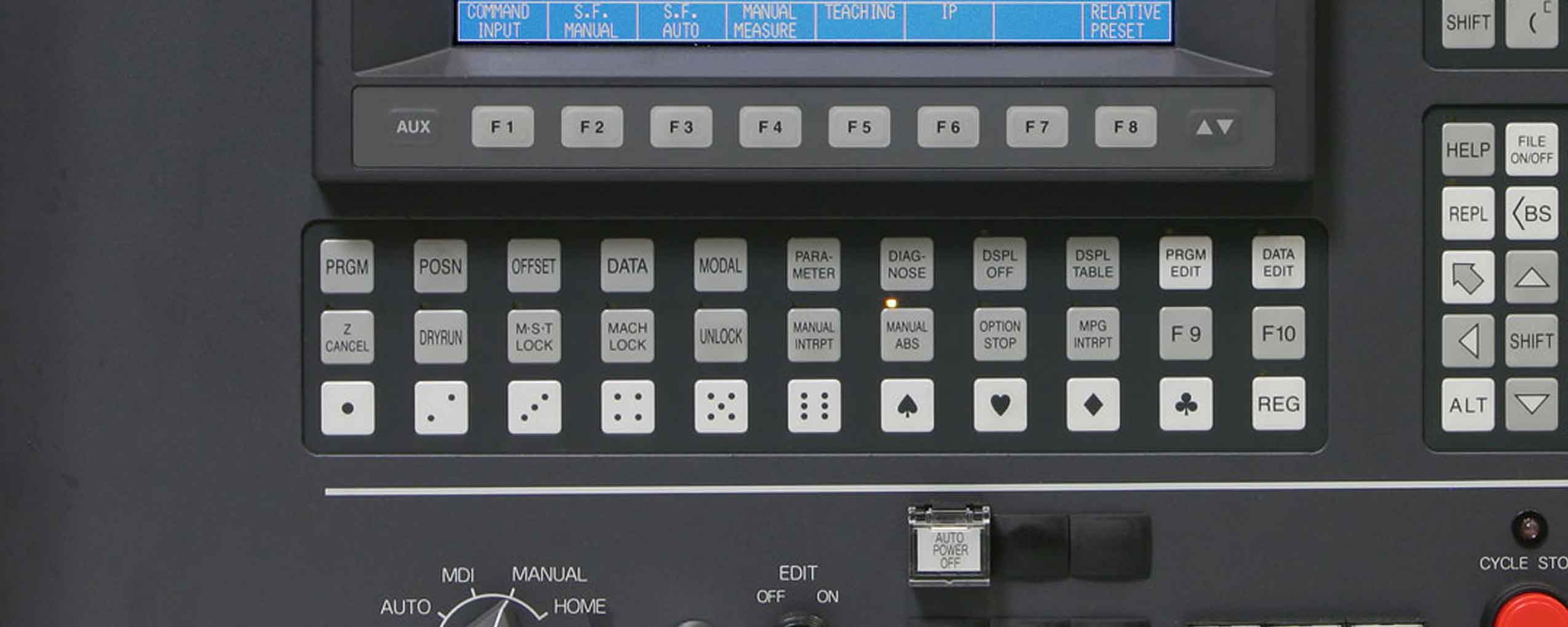

Read moreImprove CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 - While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel...

Read moreHow LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 - When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily sen...

Read moreLarge workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools