Improve Part Program Usability with the TOSNUC 999 Macro Programming Function

ELK GROVE VILLAGE, IL, February 22, 2022 -

Macro programming for CNC machining provides shops countless benefits. It offers both power and flexibility, allowing machinists to implement improvements in just about every facet of a CNC environment. Many shops utilize programming with macro to help reduce downtime, production run time, maintenance time, and simplify what can be complex tasks for setup personnel and operators.

Shibaura Machine’s proprietary TOSNUC CNC control Macro Programming Function offers features that significantly increase the usability of various part programs and make it easier to understand what the G-code is doing. As such, operators can more easily create their own cycles and improve efficiency.

Examples of Macro Programming

There are a multitude of ways to use CNC macro programming. Several popular applications include:

- Reworking parts to tell the part program the amount of variable part stock and which series of steps to execute.

- Deep hole custom drilling can be put into a subprogram, shared across the G-code and used as needed.

- Adjusting the program tool path to accommodate material variations for the same part.

- Ensure repeatability with automated setup of modular fixturing.

Being able to use these applications are just a few ways that macro programming offers improved productivity and prove to be a powerful tool on your shop floor.

How TOSNUC 999 Helps

In order to offer the machinist help with CNC macro programming the TOSNUC 999 Macro Programming Function makes the following possible:

- Part programs of several blocks can be executed in one block command.

- Variable expressions can be utilized in place of numerical value of the part program word.

- Unconditional GO and IF commands can be utilized in a part program.

- Variables can be set and changed by means of a program command.

- Values can be set to variables in the form of an expression.

- In a part program, a variable expression can be utilized in place of the numerical value of an arbitrary address word.

- A single part program can be called from another part program.

- A single part program can be modally called or by means of G or M code.

Learn More

Learn more about how the macro programming features available on the TOSNUC 999 control can help improve your shop productivity. Contact our Machine Tool team today.

Related Articles View All Machine Tools Articles

Optimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 - Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor ...

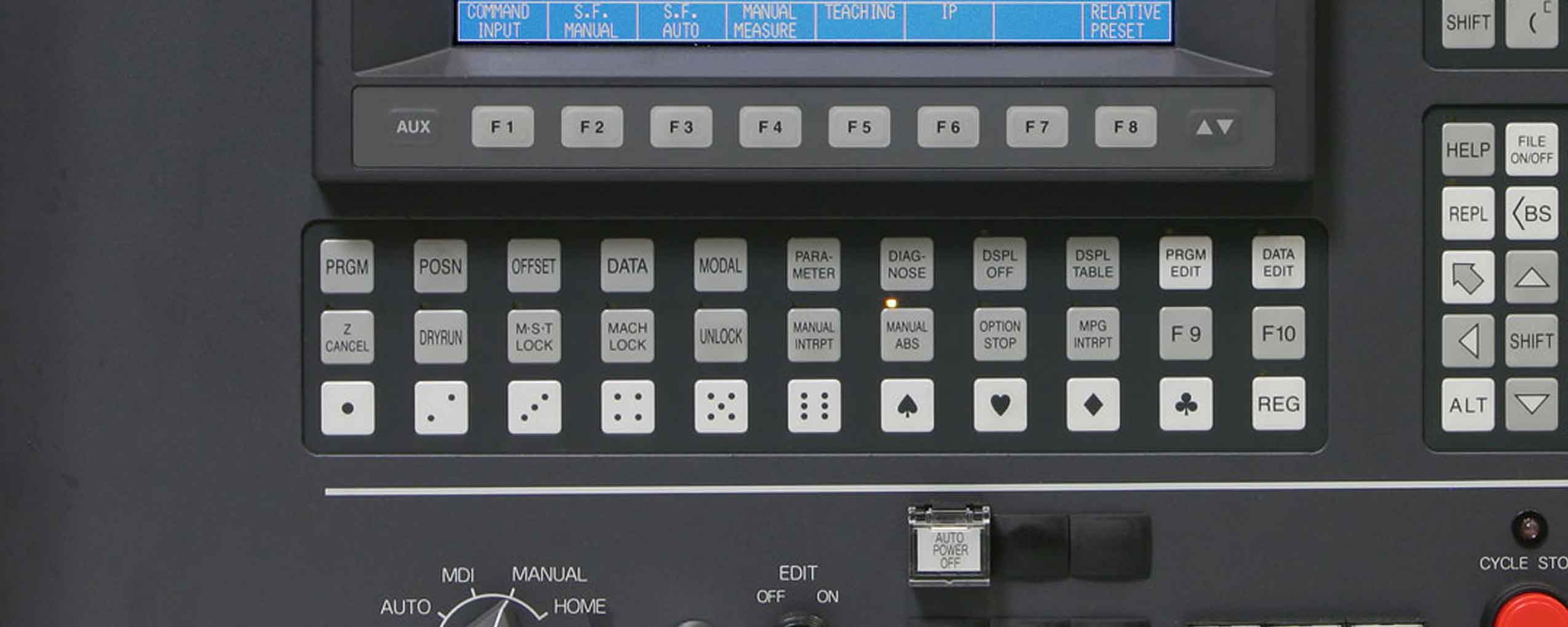

Read moreImprove CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 - While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel...

Read moreHow LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 - When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily sen...

Read moreLarge workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreMachine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

Read moreShop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, ...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools