Optimize Productivity With These Strategic Machine Shop Layout Ideas

ELK GROVE VILLAGE, IL, February 14, 2022 -

Take a look at your machine shop floor. Is it maximizing space and enabling the most productive environment?

One of the most overlooked solutions to improving workflow and production in CNC machining is shop floor organization and layout. With thoughtful design, it can not only free up extra floor space, but be one of the easiest ways to improve your bottom line.

While many shops contend with small spaces, low ceilings, or structural pillars it is not always easy to design the most effective layout, but for shops that are able to do so it brings optimized efficiency which is a true competitive advantage. Shibaura Machine is outlining three essential factors to consider when organizing or re-organizing your shop floor.

- Streamline Workflow

How many times does a workpiece cross your shop floor during its machining process? Considering the route a part takes through the shop floor is one of the best ways to maximize productivity. If workflow is traveling in a less efficient manner from beginning to end around the shop, that is a process that leaves room to be optimized.

- Group Processes Together

Along with streamlining workflow, you will want to group like-processes together. This means considering the production cycle and setting up processes that occur at similar times close to each other when possible.

For example, consider your quality control equipment and your fulfillment areas. If you can keep them close together it will better ensure that nothing is overlooked and pieces move more efficiently from inspection to storage.

- Employee Safety & Productivity

We all know that safety is crucial. It also creates a trickle down effect, because a safe employee is happy and a happy employee is overall a more productive employee. Create your shop layout with safety in mind, assess it for hazards, dangerous materials, etc. and make sure employees understand workflow and emergency protocols.

Also consider equipment and tooling locations. Making sure tools, clamps, and other equipment are easily accessible and organized can have a big impact on employee efficiency and productivity.

Optimize Your Workspace

Putting these considerations into practice can not only maximize your space, but improve productivity and increase safety. Contact the Machine Tool team for advice on the placement of your Shibaura Machine Tool.

Related Articles View All Machine Tools Articles

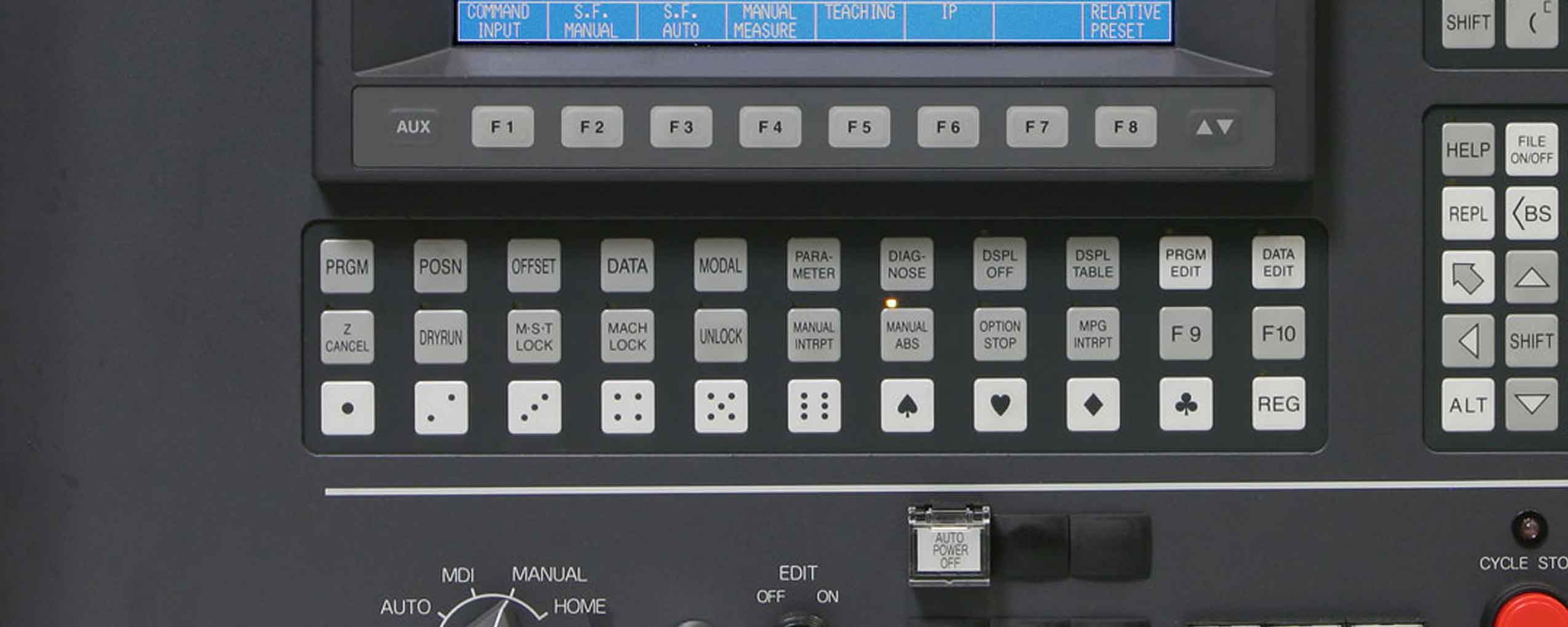

Improve CNC Operation Efficiency with Customized Keys on TOSNUC 999

ELK GROVE VILLAGE, IL, February 08, 2022 - While CNC machines are excellent at doing what they are programmed to do, it is the machine operator's role to make sure they are commanded accurately. That is why being able to properly navigate the control panel...

Read moreHow LAN Linkage is Improving Operational Efficiency

ELK GROVE VILLAGE, IL, January 31, 2022 - When it comes to connecting a CNC machine to your network, doing so benefits the bottom line by increasing productivity and improving uptime. With local area network (LAN) connectivity, shops are able to easily sen...

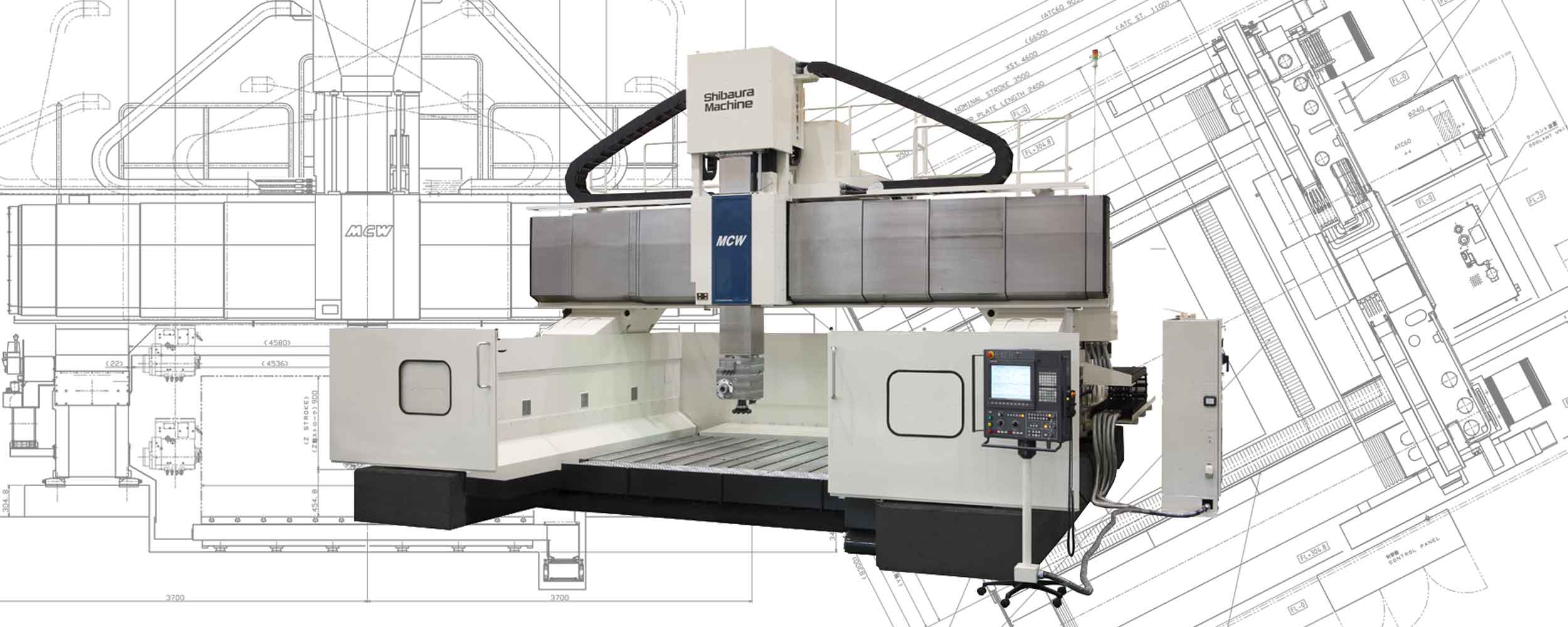

Read moreLarge workpiece, but short on space? Here’s your solution.

ELK GROVE VILLAGE, IL, January 24, 2022 - Machine tools that can meet the demands of large parts and difficult to cut materials while providing increased efficiency and precision are in growing demand. Industries like oil and gas, automotive, aerospace, mi...

Read moreMachine Tool Operations Made Simple with the Manual Pendant

ELK GROVE VILLAGE, IL, January 17, 2022 - Any way that efficiency can be improved is important in the competitive world of machining. Improving efficiency not only helps cut costs, but throughput of the shop. And while there are plenty of ways to improve p...

Read moreShop Floor Programming with Manual Guide i

ELK GROVE VILLAGE, IL, January 12, 2022 - Improving production cycle times is a top shop goal to achieve this year. Conversational and/or shop floor programming software has quickly become a popular option to help meet these goals. Without knowing G-code, ...

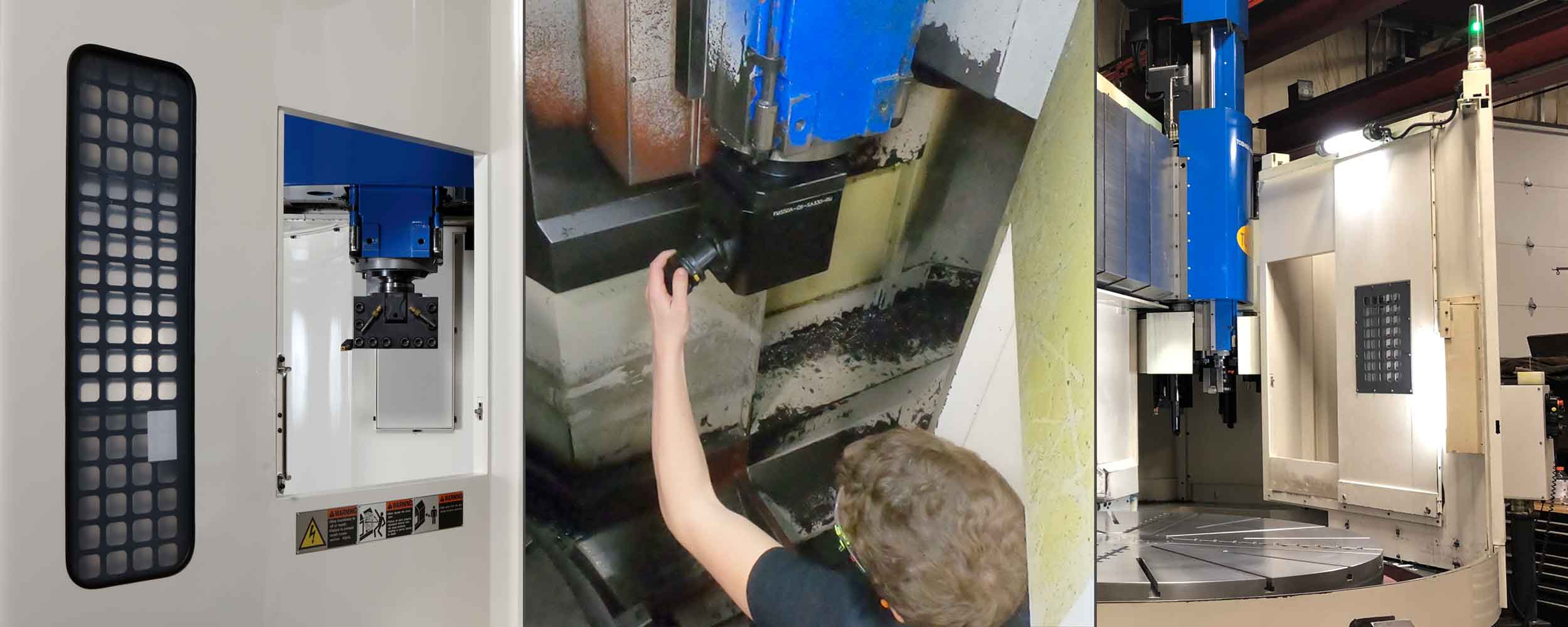

Read moreReduce Tool Changeover Times with Convenient Access Door

ELK GROVE VILLAGE, IL, January 5, 2022 - A machine operator knows that a tool holder provides a safe critical interface between the cutting tool and the spindle of the machine. With the cutting tool mounted in the holder, it provides the stability to ensur...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools