Taking LSR Molding to a Higher Level with All-Electric Technology

ELK GROVE VILLAGE, IL, August 20, 2021 -Liquid silicone rubber molding is experiencing demand growth like never before in North America. While many manufacturers are considering whether to invest in a dedicated liquid silicone rubber (LSR) molding machine, what if you could have an all-electric LSR machine with the option to convert to thermoplastic molding if needed?

Shibaura Machine’s all-electric injection molding machine offers shops just that. This affordable, repeatable machine offers manufacturers the ability to grow their LSR molding business, while providing the option to convert back to thermoplastic. And because no hydraulic oil is needed, this all-electric machine offers less potential for contamination compared to hydraulic counterparts.

Why Choose LSR?

LSR molders enjoy easy repeatability, quick time to market, and added design flexibility to achieve complex part features and consistencies. This makes the process popular in a variety of industries including medical, automotive, infant care, general industrial markets, aerospace, and electronics. One of the biggest reasons for choosing LSR is that properties and the material remain stable over a range of extreme temperatures — whether hot or cold.

Advantages of Shibaura Machine’s LSR Technology

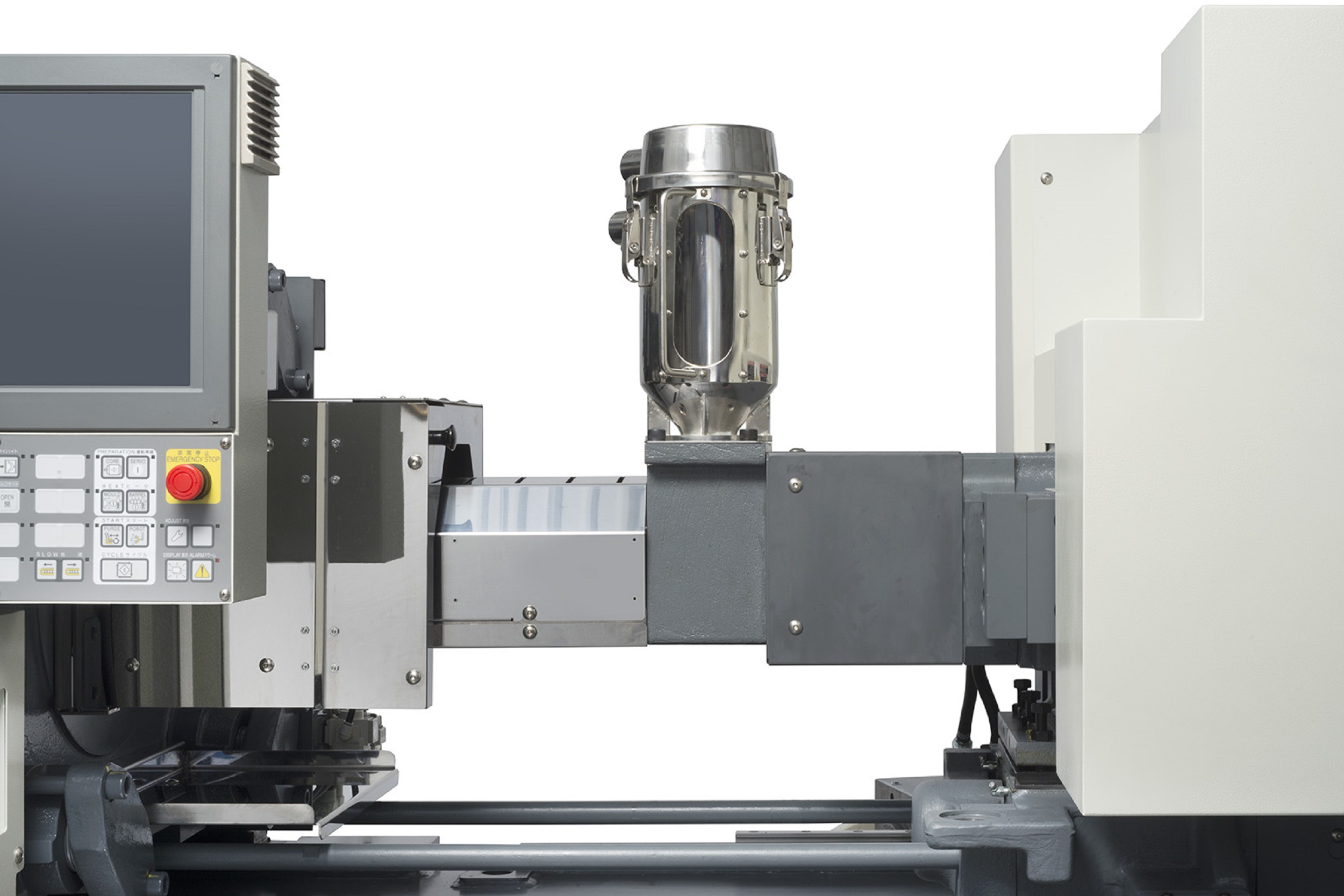

Shibaura Machine’s state-of-the-art All-Electric Injection Molding Machine offers a reliable and fully integrated LSR technology.

Specific features to the machine include:

- Quick Release LSR Barrel

- Easy to Maintain Water Jacket

- On Screen Control of HR

- 8 Zone Water Distribution (option to add up to 12)

- Water Cooled Platens

- Spring Loaded Poppet Non-Return Valve

- CPM Zero Compression Screw with Non-Shear Mixer

- Liquid Silicone Style Water-Cooled Pneumatic Shut-Off Nozzle

- 14:1 ~16:1 L/D CPM Zero Compression Screw

- Programmable Outputs

- Dual Air Blow

Also available as optional features: vacuum for mold venting, LSR pumping station, and static mixer.

The machine also includes a fully-integrated 8 zone mold heat control for LSR molds or thermoplastic use (option up to 24 Zones), quick power disconnect and thermocouples on thermoplastic barrel, as well as water cooled tungsten carbide barrel for LSR.

All-Electric LSR Molding

Being able to employ both molding processes in one machine not only saves space, but improves capital equipment investment. The benefits of LSR technology provide consistency and cost-effectiveness for a wide variety of applications. Contact the injection molding team at Shibaura Machine to learn more about how our all-electric technology is an ideal fit for LSR molding.

Contact us today to learn more abut our all-electric LSR molding solutions!

Related Articles View All Articles

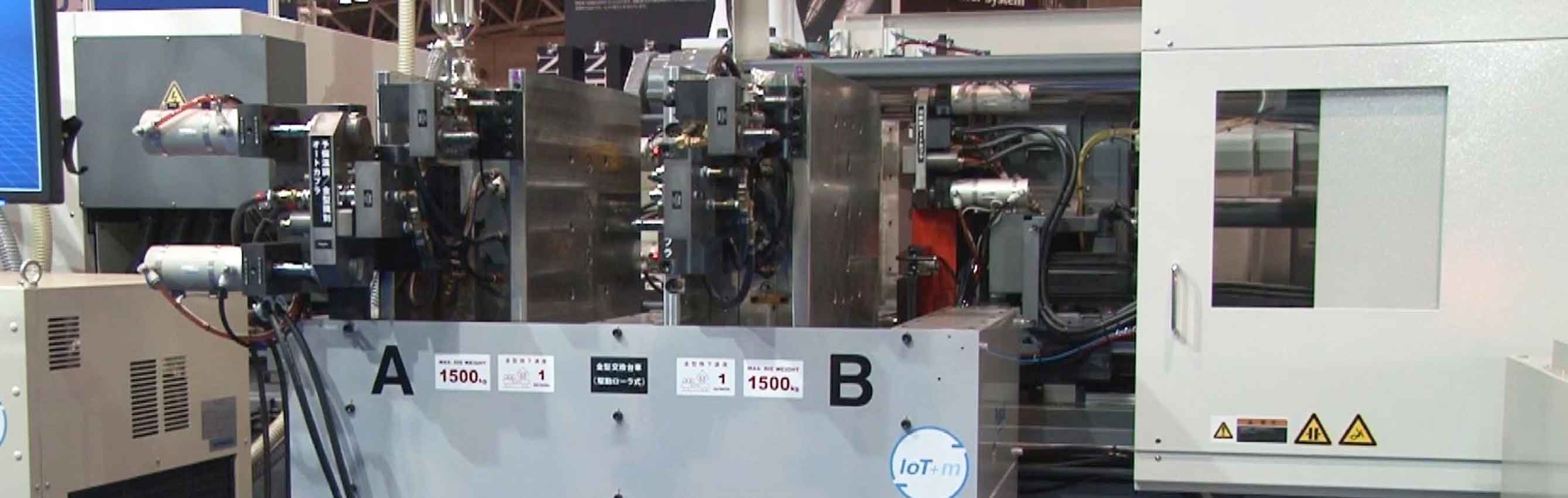

Two-Shot Molding: Any Machine, Any Time with Shibaura Machine

ELK GROVE VILLAGE, IL, August 6, 2021 - Two-shot molding is one of the most efficient processes for manufacturers creating products using plastics. By allowing operators to create multi-material or multi-colored parts without adding extra assembly steps it...

Read moreInjection Molding Energy Consumption At a Glance

ELK GROVE VILLAGE, IL, July 28, 2021 - From energy hogs forty years ago to the efficient all-electric options of today, injection molding machines have made quite the evolution. While injection molding is still an energy intensive process, the all-electric...

Read moreFrom One Product to the Next- Improving Set-up Efficiency in Injection Molding with SMED and the SXIII

ELK GROVE VILLAGE, IL, July 7, 2021 - Reducing the changeover time for your operations is critical to maintain a competitive advantage and improve profitability in the manufacturing industry today.That’s where the concept of single-minute exchange of die, ...

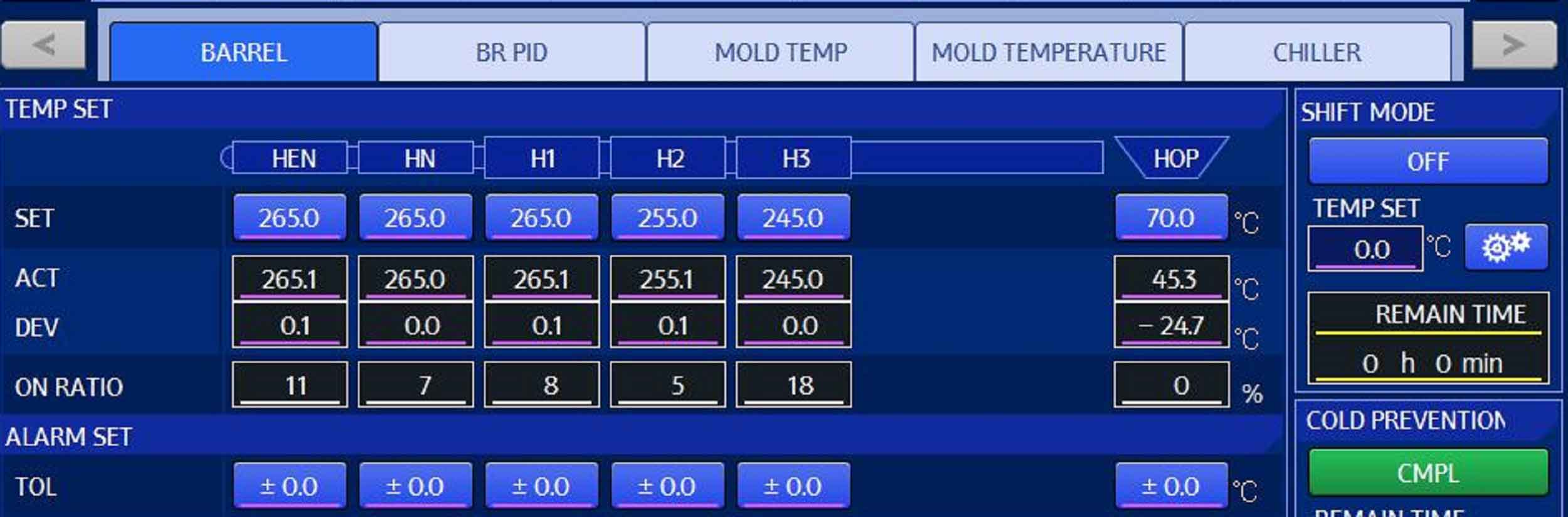

Read moreGain Control Over Your Barrel Temperature with Shibaura Machine’s V70 Controller

ELK GROVE VILLAGE, IL, June 25, 2021 - Errors in temperature control result in a large part of rejects in the injection molding world. If a molder wants to ensure a stable molding cycle and high quality product, having a temperature control process is esse...

Read moreUsing Auto-Purge to Improve Injection Molding Efficiency

ELK GROVE VILLAGE, IL, June 23, 2021 - Molders today are always looking for a way to minimize their losses. So while purging is often necessary, it makes many molders cringe because this process often means costly waste and lost production time- defeating...

Read moreMold Recipe Management: Saving Time and Money in Injection Molding

ELK GROVE VILLAGE, IL, June 9, 2021 - Think of a chef on a Friday night at a popular restaurant. They are tasked with switching from one recipe to the next in a single night. Not only that, they need to make sure they use the correct measurements, with qui...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools