Reducing Cycle Times in Injection Molding: How All-Electric Has Changed the Game

ELK GROVE VILLAGE, IL, May 27, 2021 - Why is reducing cycle times such a popular topic in injection molding? Largely because from both a time and cost standpoint the effects of even a few seconds improvement on your cycle time can have a major impact on your bottom line.

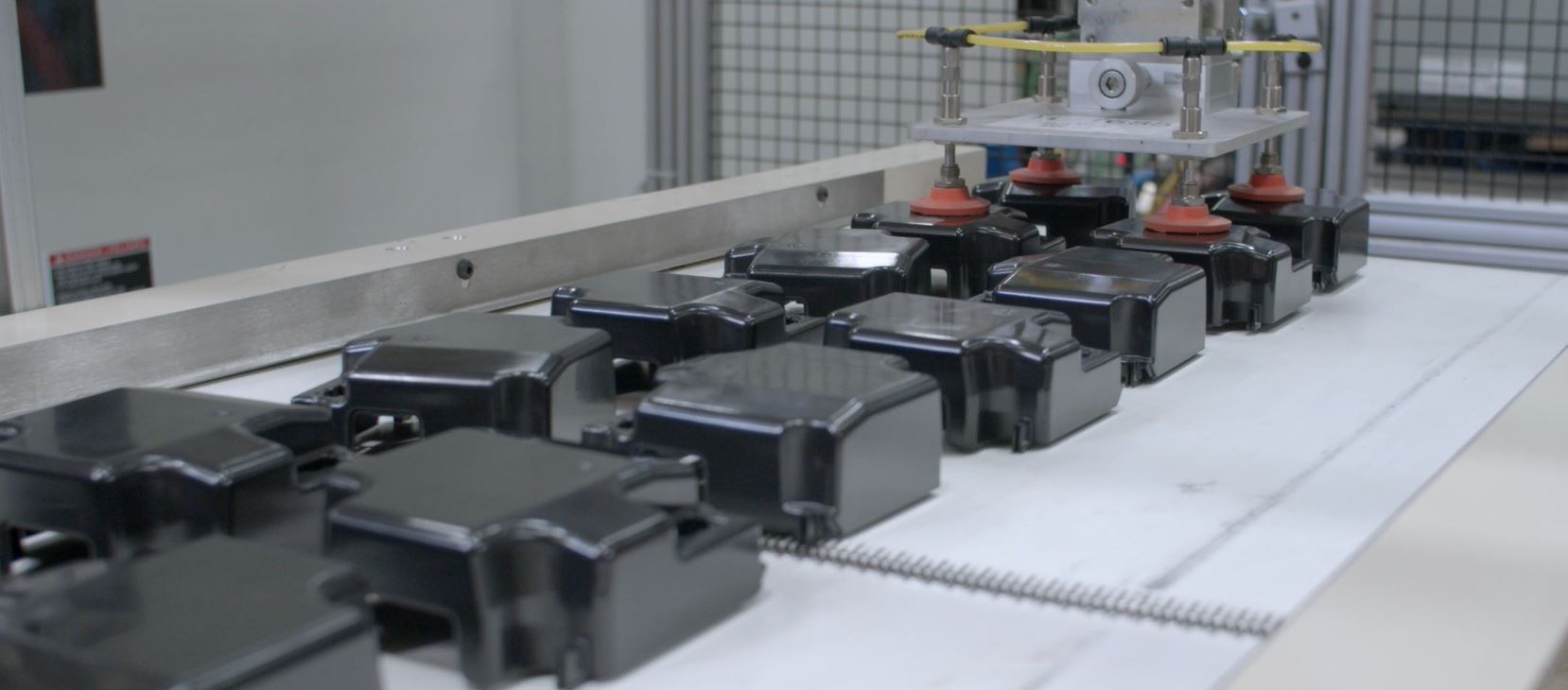

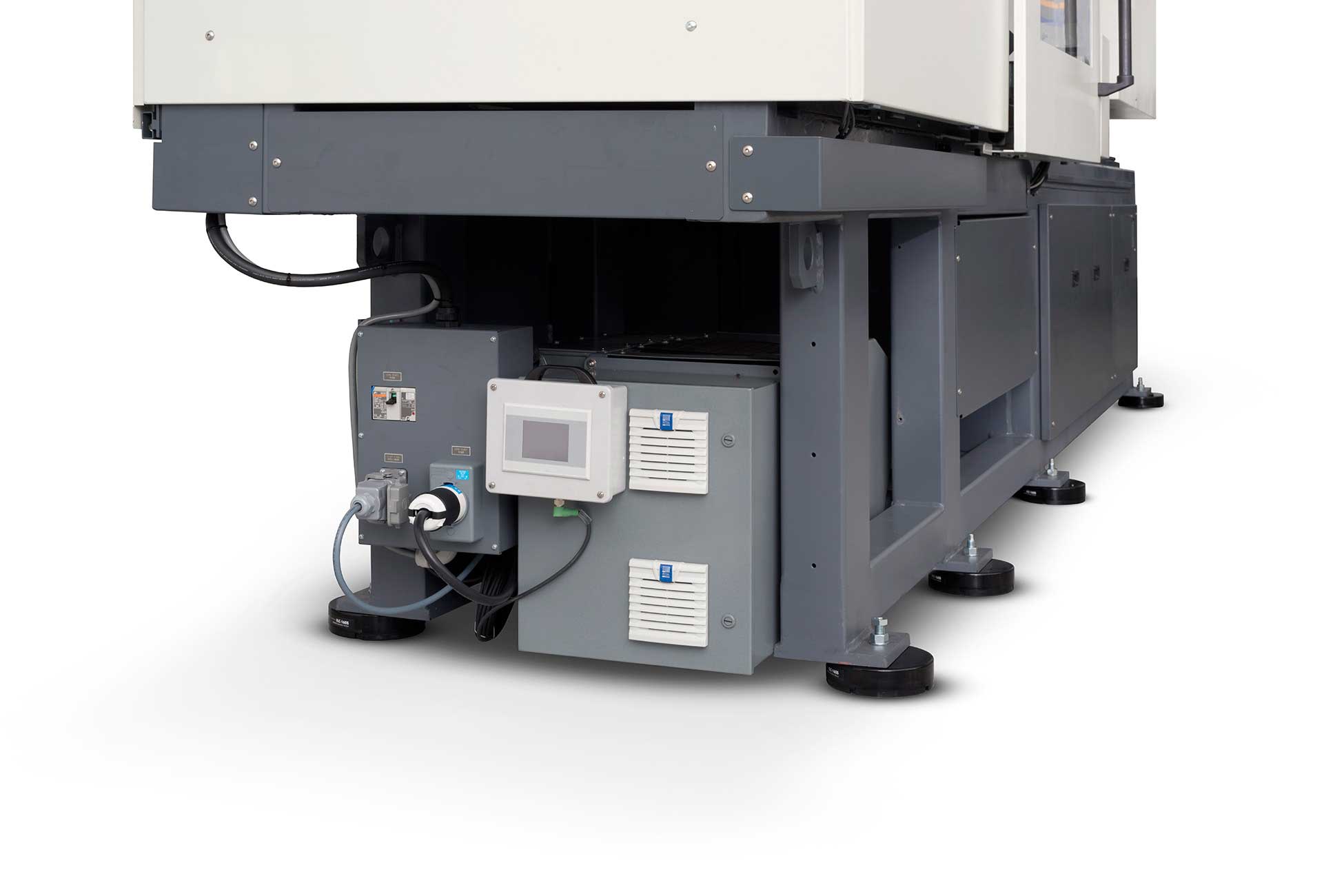

While you can implement different methods to improve efficiency, some injection molding machines will always simply be better at reducing cycle times then others. As technology has advanced, the all-electric injection molding machine has stood out as a clear winner compared to their hydraulic or hybrid injection molding machine counterparts. Shibaura Machine’s ECSXIII all-electric injection molding machines can make compound movements in ways hydraulic injection molding machines simply can not.

High Speed Injection Molding

Simultaneous motions ultimately means higher speed injection molding. Cycle times can be improved by up to 30% through simultaneous motions and high speed movement.

The ECSXIII all-electric Shibaura machines come standard with multiple electric servo motors to allow them this capability from the start. Unless expensive upgrades for additional pumps are purchased, the hydraulic machines typically can allow for one movement at a time because they usually only have one hydraulic pressure circuit to actuate movements.

All-Electric Machine Functions to Reduce Cycle Times

The independent nature of the servo motors controlling the all-electric machines allows for multiple functions to occur simultaneously.

- With eject-on-the-fly you can improve cycle time and in most cases the mold can open and close without a pause for ejection.

- LAP sequence allows injection to start as soon as the mold halves touch. This provides better venting within the tool.

- Relax clamp during cooling in order to take more time off the cycle.

- Additional simultaneous motions that reduce cycle times include opening the mold while charging, pulling the core in and out on the fly, and ejectors retracting during mold close.

Start Improving Efficiency Beyond Expectation

Reducing cycle times and maintaining an efficient process go hand in hand. Simultaneous motions and high speed movement are standard on Shibaura Machine all-electric ECSXIII models. Even at top speed the ECSXIII Shibaura machines continue with the same precision and accuracy allowing you to keep your competitive advantage.

Contact Shibaura Machine’s injection molding team to learn more about reducing cycle times with the ECSXIII series.

Contact us today to learn how our ECSXIII all-electric machines can help your shop become more productive!

Related Articles View All Articles

Standard Pneumatic Features Maximize Your Injection Molding Machine Investment

ELK GROVE VILLAGE, IL, May 19, 2021 - Have you ever gone shopping for a car? The answer for most of us is probably yes. You know you’re making an investment in a vehicle that you will likely have for years to come and want it to be just so. While many feat...

Read moreUsing Programmable Outputs to Improve Injection Molding Productivity

ELK GROVE VILLAGE, IL, May 12, 2021 - The demand for quality parts quickly continues to grow. Shop floors are working to meet customer requirements and being able to boost efficiency in production is key. Having the flexibility of connecting auxiliary equi...

Read moreShibaura Machine Makes Core Pull on All Electric Injection Molding Machines Simple

ELK GROVE VILLAGE, IL, May 5, 2021 - Many molds rely on core pull in order to produce their final product successfully. Whether it’s a hollowed out container, unscrewing features in the tool, or ejecting parts- the core pull feature provides shops a way to...

Read moreIntroducing Injection Molding “Tech Talk Thursday” Webinar Series

ELK GROVE VILLAGE, IL, April 22, 2021 – Profitability and competitive advantage. These are two things factories strive for when it comes to their injection molding operation. Owners and operators alike are continually working to be as efficient as possible...

Read moreServices to Keep Your Injection Molding Machines Running Efficiently

ELK GROVE VILLAGE, IL, April 14, 2021 – High quality parts come from high quality machinery. In order to keep your injection molding machines running efficiently with minimal downtime it's important to have the backing of a strong service team. Most moldin...

Read moreMinimize Injection Molding Downtime with a Good Parts Partner

ELK GROVE VILLAGE, IL, April 8, 2021 – Even with impeccable maintenance, your injection molding machine will find itself needing spare parts at some point. When that time comes, having a machine partner that can get you the correct part easily and efficien...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools