Standard Pneumatic Features Maximize Your Injection Molding Machine Investment

ELK GROVE VILLAGE, IL, May 19, 2021 - Have you ever gone shopping for a car? The answer for most of us is probably yes. You know you’re making an investment in a vehicle that you will likely have for years to come and want it to be just so. While many features come standard, there are usually several that don’t, but you know you’d utilize and get value out of them. By the end of the shopping experience you’ve likely either tacked on these features which means additional costs or you have to figure out how to add them on aftermarket once budget allows.

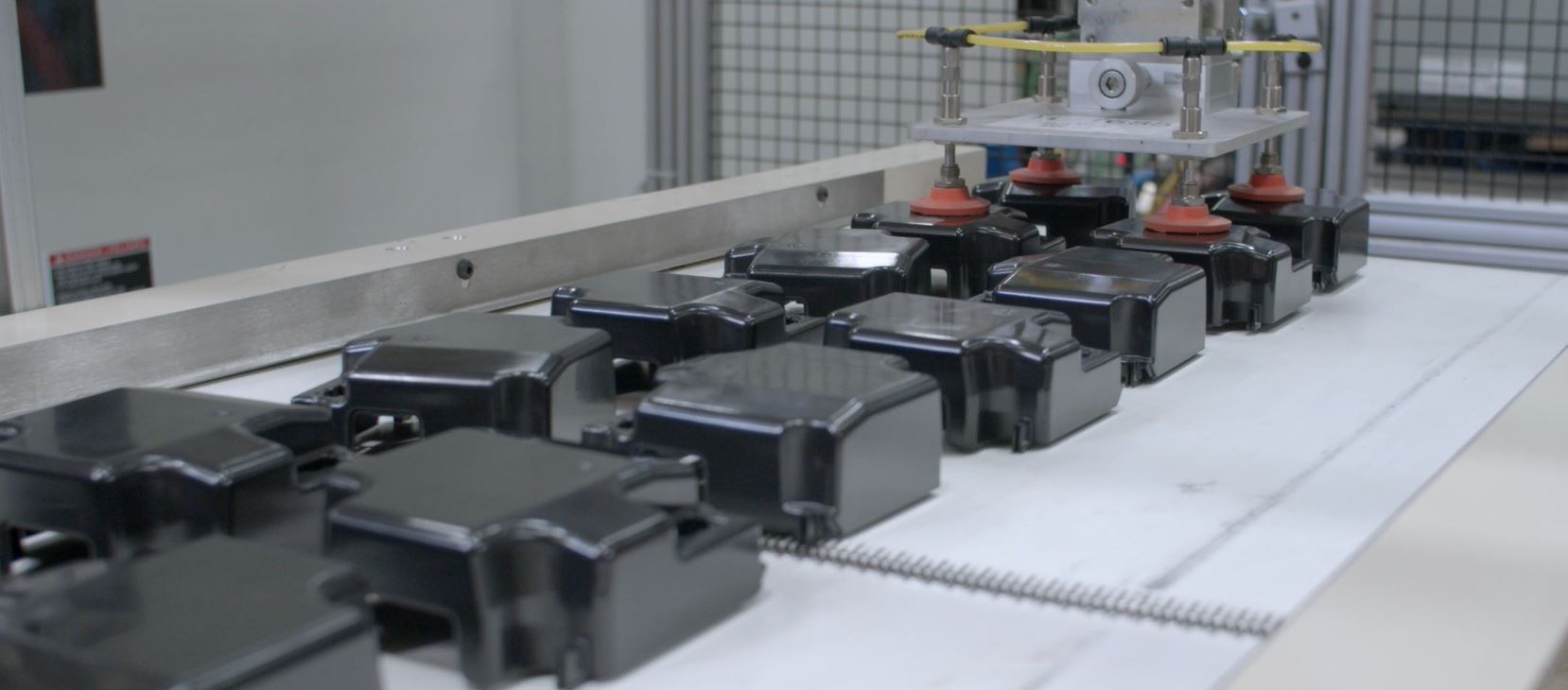

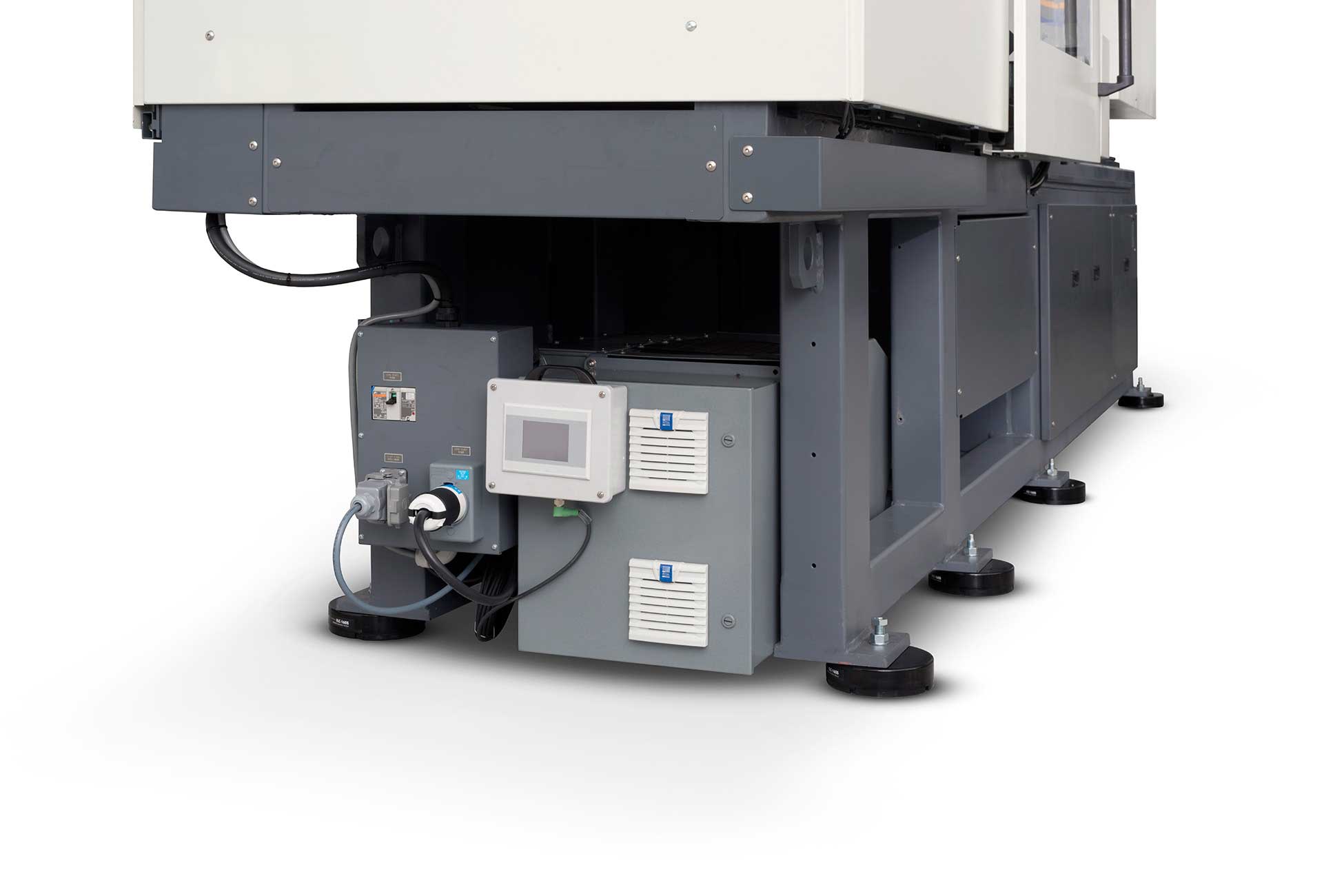

Investing in an injection molding machine oftentimes is a similar experience. You find a machine, but it doesn’t have all the features you require to obtain maximum value for your investment and you end up adding on additional items for additional dollars. Shibaura Machine believes it doesn’t have to be this way. Our ECSXIII series injection molding machines come standard with a variety of pneumatic features that allow customers to maximize their initial investment.

Changing the Standard

Shibaura Machine remains committed to help in the transformation of the manufacturing industry. The ECSXIII series was developed with a suite of pneumatic features that come standard in order to help our customers maximize the machine's value and improve productivity by making it easier to run a variety of molds.

- Dual Air Blow Circuit – Parts can be difficult to eject from a mold based on their size or shape. The dual air blow circuit allows the user to set-up two stages of air blow to assist with ejection of parts from the mold. It can be synchronized with the mechanical ejectors to help ensure proper ejection of the parts.

- Single Zone Pneumatic Core Pull – In some cases a mold may require a pneumatic core pull circuit to help with certain applications. This feature affords our customers the ability to run a wider variety of molds.

- Single Zone Pneumatic Valve Gate – Certain molds are designed using valve gates to accurately control the flow of material, eliminate material drool and gate string, improve physical properties with lower molded-in stress, and cycle time reduction.

To maximize your investment Shibaura Machine believes it is important to have access to a comprehensive suite of pneumatic features. These standard features are complimented by Shibaura Machine's years of injection molding expertise, creating a winning combination to boost productivity and improve cost-effectiveness.

If you are interested in learning more about the ECSXIII series standard pneumatic features contact our injection molding team today by clicking below!

Contact us today to learn how our standard pneumatic features can make your shop more productive!

Related Articles View All Articles

Using Programmable Outputs to Improve Injection Molding Productivity

ELK GROVE VILLAGE, IL, May 12, 2021 - The demand for quality parts quickly continues to grow. Shop floors are working to meet customer requirements and being able to boost efficiency in production is key. Having the flexibility of connecting auxiliary equi...

Read moreShibaura Machine Makes Core Pull on All Electric Injection Molding Machines Simple

ELK GROVE VILLAGE, IL, May 5, 2021 - Many molds rely on core pull in order to produce their final product successfully. Whether it’s a hollowed out container, unscrewing features in the tool, or ejecting parts- the core pull feature provides shops a way to...

Read moreIntroducing Injection Molding “Tech Talk Thursday” Webinar Series

ELK GROVE VILLAGE, IL, April 22, 2021 – Profitability and competitive advantage. These are two things factories strive for when it comes to their injection molding operation. Owners and operators alike are continually working to be as efficient as possible...

Read moreServices to Keep Your Injection Molding Machines Running Efficiently

ELK GROVE VILLAGE, IL, April 14, 2021 – High quality parts come from high quality machinery. In order to keep your injection molding machines running efficiently with minimal downtime it's important to have the backing of a strong service team. Most moldin...

Read moreMinimize Injection Molding Downtime with a Good Parts Partner

ELK GROVE VILLAGE, IL, April 8, 2021 – Even with impeccable maintenance, your injection molding machine will find itself needing spare parts at some point. When that time comes, having a machine partner that can get you the correct part easily and efficien...

Read moreHow Injection Molding Training Maximizes Your Machine ROI

ELK GROVE VILLAGE, IL, April 1, 2021 – Having a comprehensive understanding of your injection molding machine will not only improve your production processes, but overall profitability. Setting this type of foundation is not only a smart investment in your...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools