Improve Quality Control and Productivity with the iPAQET Remote Data Management System

ELK GROVE VILLAGE, IL, January 27, 2021 – Not all monitoring and data management systems are created equal. Many systems are prone to errors, have less than easy to use interfaces, or require someone to be in front of the machine- oftentimes collecting data manually. What if you could be off site and still monitor critical components during operation, collecting and analyzing the data you require?

The iPAQET Remote Monitoring & Data Management System by Shibaura Machine provides the information required to effectively manage equipment, production, and product quality from inside the plant or remotely. Compatible with Shibaura Machines equipped with the V30, V50, or V70 controllers it offers unparalleled visibility of your operations from anywhere. With the iPAQET system your molding shop will be equipped to improve productivity and better monitor quality- helping you meet your production goals.

iPAQET Intuitively Makes Management Simple

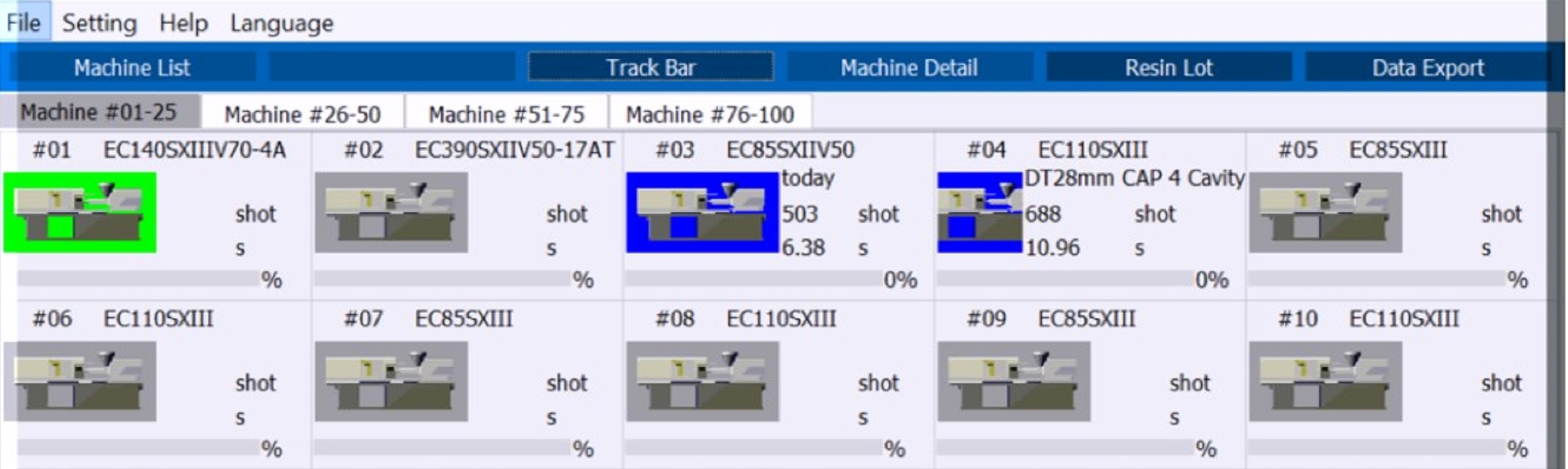

The iPAQET real time data collection system allows you to quickly view machine and production status with our easy to use interface and graphics. By using a LAN line you will have a central viewing of production information and the ability to message up to 100 machines. The system offers an accurate and easy way to manage machines, products, quality, and run quality analysis.

Tools available include:

- Process management

- Production management

- Machine history log

- Quality management

- Real time machine status

- Resin lot management/traceability

iPAQET is Innovation

iPAQET frees up plant personnel for more valuable tasks by automating often tedious and error-prone work. iPAQET was designed with several features that allow injection molders to achieve greater productivity:

- Improved Visibility: real-time machine/assembly station status and production quantities

- Easy Accountability: know which operator produces what and how fast

- Real Time Continuous Improvements: problem notifications and problem/solution history

- Reduced Machine Downtime: get notifications when machine status changes

- Profit Awareness: the system provides information to help you calculate your true costs

We are committed to offering our customers the most innovative ways to cut costs permanently. The iPAQET remote data management system allows for optimal monitoring and analysis of the injection molding process. This powerful system gives you the highest level of production data available in the industry today.

Want to learn more about how iPAQET Data Management can add value to your operation? Request more information below!

Related Articles View All Articles

How to Minimize Injection Molding Machine Downtime

ELK GROVE VILLAGE, IL, January 19, 2021 – Whether planned or unplanned, machine downtime is very costly. Aside from directly impacting production and labor, machine downtime extends to other areas of operation and can affect the organization as a whole. An...

Read moreReducing Reject Rates for Injection Molding is Within Reach

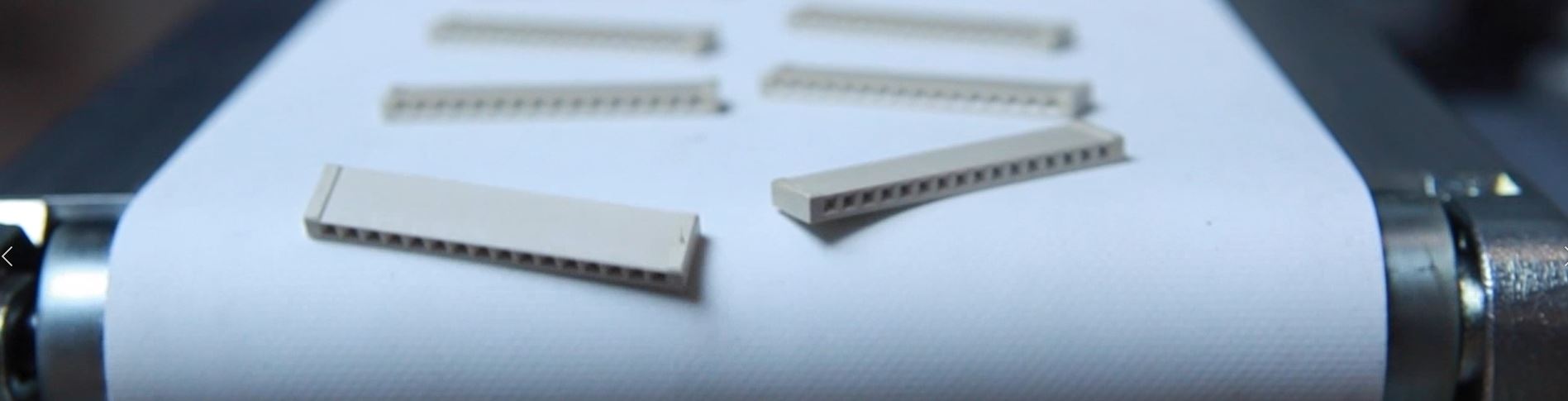

ELK GROVE VILLAGE, IL, January 13, 2021 – If parts are considered defective they are likely getting rejected by customers. That means the cost lands on you, but with a premium because you have equipment and labor costs tied into it. Luckily, the right inje...

Read moreReducing Injection Molding Cycle Times Using All-Electric Technology

ELK GROVE VILLAGE, IL, January 5, 2021 – When it comes to improving manufacturing processes, optimizing the parameters of your injection molding machine is critical. Specifically, working to reduce cycle times in injection molding can allow you to produce ...

Read moreEvolving with Our Injection Molding Customers through Superior Support

ELK GROVE VILLAGE, IL, December 29, 2020 – Making an investment in an injection molding machine is as much about the people behind it as the machine itself.Having a true partner that works to find ways to minimize downtime, improve efficiency, and keep you...

Read morePut Our Injection Molding Expertise to Work for You

ELK GROVE VILLAGE, IL, December 23, 2020 – Navigating a challenging year meant adapting new ways to serve customers for many industries. For manufacturers, it meant figuring out ways to increase plant efficiencies and optimize their current processes. Havi...

Read moreBenefits of Financing Capital Equipment

ELK GROVE VILLAGE, IL, December 16, 2020 – Having the right equipment gives your business a significant advantage. Without proper financing, obtaining that equipment can significantly impact your company’s cash flow.That is why Shibaura Machine has assembl...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools