Shot Cylinder Construction is More Important Than One Would Think

ELK GROVE VILLAGE, IL, April 15, 2021 -

Have you ever heard the saying that too many cooks in the kitchen spoil the broth? This expression can also be applied to die casting machine shot cylinder design.

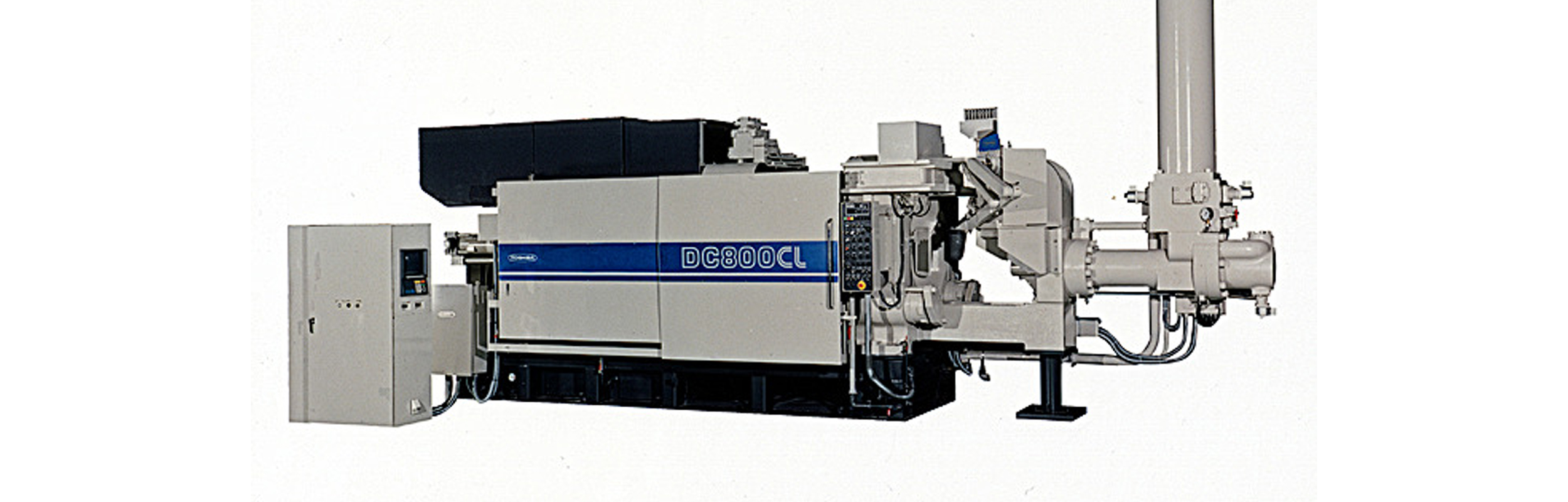

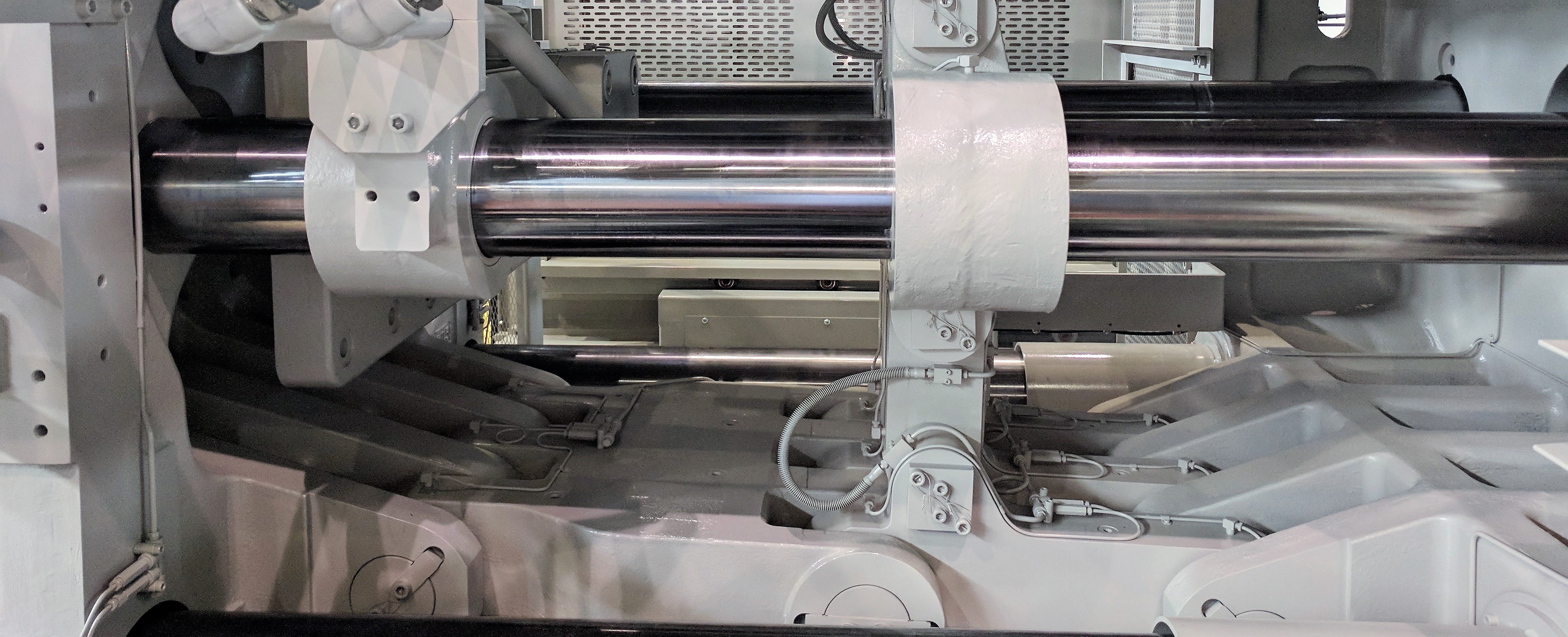

Consider early generation and many current-day die casting machines, the conventional design has been to bolt numerous pipes, fittings, and hoses at the shot end to move the cylinders (See picture below). What was supposed to be a simple cylinder pushing metal into the die has suddenly turned into a convoluted mess of too many components and connections. All of this makes it easier for the machine to break down, leak oil, and require more maintenance.

Shibaura Machine decided there had to be a better way. A way that will not only mean less maintenance and downtime, but increase the durability of the die casting machine. With this idea in mind, since the 1970’s onward our team has modernized our die casting machine shot cylinder design.

The Benefits of Turning Many into One

Shibaura Machine was looking to the future when they updated the design, in doing so it reduced points of failure while improving machine lifespan. Moving away from the conventional cylinder “messy design”, Shibaura Machine started using a single large casting to house the moving elements. The auxiliary pieces and hydraulic valves are then bolted onto the casting.

This modern design ensures:

- Less possible points of leakage by reducing connecting points

- Maintenance greatly reduced and the casting makes overall maintenance easier

- More durable, heavy weight system to offset the heavy vibration from shots improve machine life

Many machine builders today still stand behind the conventional cylinder design in the die casting machine shot end. However, a big problem with this conventional design is that it forgets about the future. Many of these shot ends use welded pipes and bolted on components resulting in a higher probability of failure every day. Numerous connection points leave a higher likelihood of leaks and issues. Also, these lower weight cylinders take in the heavy shot vibrations and extremely high hydraulic pressure, not being a good combination for components' life. All of these factors can hinder your investment.

Machines Designed to Last

Contact our die casting machine team to learn more about our industry leading innovation and put it to work for your factory.

Related Articles View All

Our Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 - As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ...

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools