Die Casting Factory Accessory Integration Improves Productivity

ELK GROVE VILLAGE, IL, April 2, 2021 -

Die casting has evolved a lot over the past one hundred years.

At the beginning it was run solely by what a person could accomplish. Workers were expected to be the timers, electronics, and robots that we now have today. Slowly a shift happened and the machines began to be factory made, but workers were still required to operate levers and additional accessories in order to achieve the required results.

Flash forward to this century and machines are regulated by controls, but still lack required accessories to offer full automation. This is where aftermarket automation companies come in to provide auxiliary add-ons such as ladlers, sprayers, and extractors that complete the solution.

From the start, Shibaura Machine removed the need to go to aftermarket companies for automation solutions. We saw this as being able to offer our customers a competitive advantage by increasing their productivity. By using Shibaura Machine auxiliary accessories that means they are a true part of the die casting machine from the start, offering an immediate tailor made solution for each customer.

Integrated Auxiliary Equipment Boosts Productivity

Think of a home theater system. Usually it starts with a television, surround sound speakers, perhaps a DVD player, or even a gaming system. This means more wires, more remotes which adds up to more work and knowledge to operate it. What if you could have one control system, without all the wires?

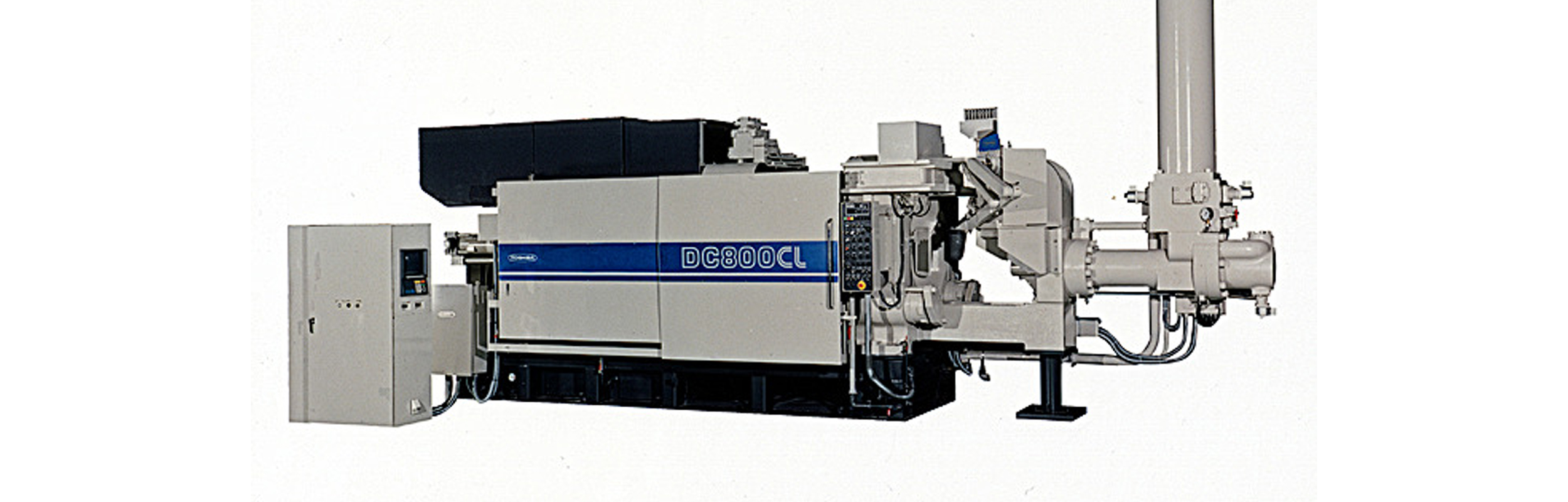

By integrating our auxiliary die casting accessories into our die casting machines, Shibaura Machine’s TOSCAST control system manages all the devices. This means that the machine is in control of all devices, giving the operator a single monitoring system and control over the entire die casting system.

This type of integration creates one single logic- that means one lock out, one emergency stop circuit. It makes diagnosing, troubleshooting, and programming not only easier, but also quicker.

Shibaura Machine’s die casting machines also have been designed to recall setup information of the auxiliary equipment. This means that your factory automation accessory settings are saved as part of the die recipe, with no need to change programs on independent control boxes as required on aftermarket auxiliary automation devices. Depending how many accessories you have, this can be a major time saver for the operator!

Changing the Standard in Die Casting

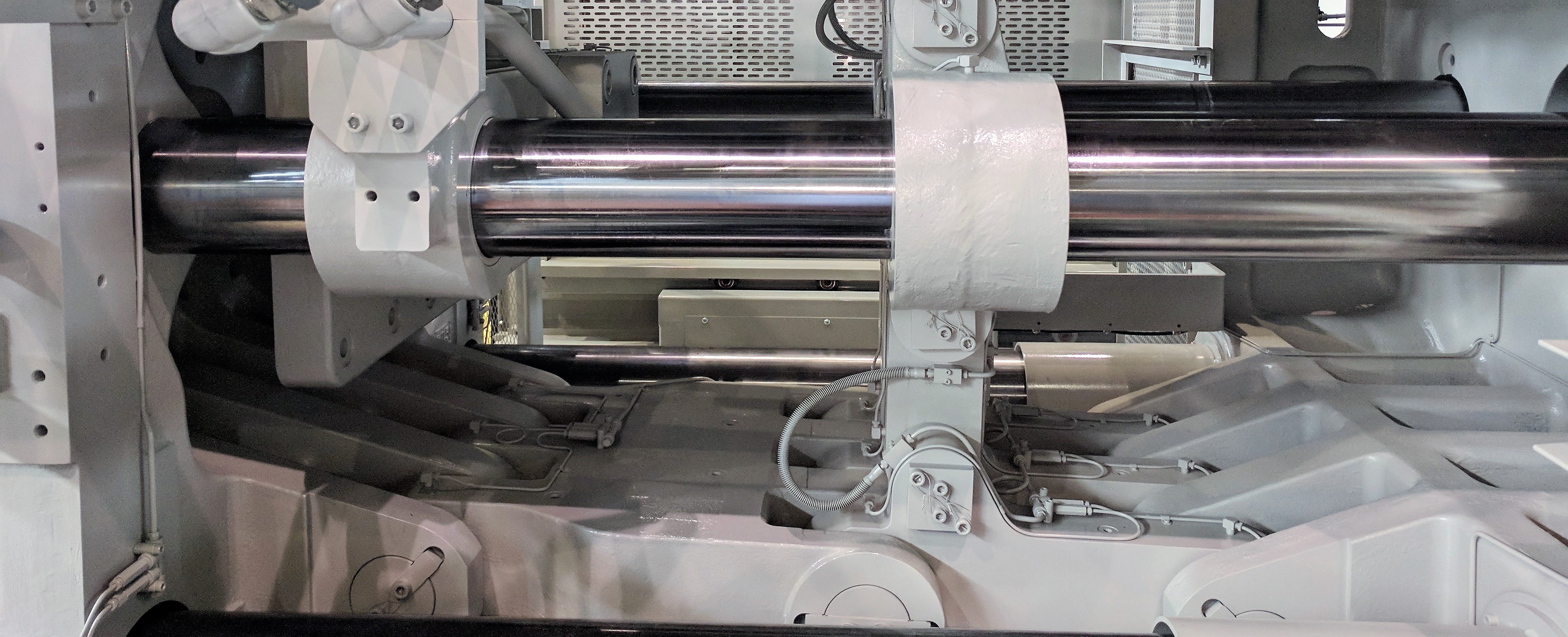

Shibaura Machine’s commitment to continual innovation and striving towards excellence in design for our customers means that we are able to offer machines that improve productivity and optimize your die casting processes.

Contact the Shibaura Machine die casting team to learn more about how our auxiliary accessories are integrated into our die casting machines.

Related Articles View All

Our Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 - As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ...

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools