Considerations for Reducing Die Casting Cycle Time

ELK GROVE VILLAGE, IL, January 5, 2021

When it comes to die casting, cycle time optimization is more than just moving quickly.

At first thought, the time required to complete castings should be as short as possible because more money can be made if you produce more parts per minute. But the world of die casting simply isn’t a minute to minute science.

Optimizing the die casting process is much more than moving as quickly as you can. We are sharing insights to consider for your die casting operations and the pros and cons of cutting time off your cycles.

The Importance of Correct Operation

Don’t worry so much about tasks like the three seconds to open, because you will likely find yourself paying for damages in the long run if you try to shave a second off. Doing the basic sequence of events correctly is more important to the time-cost savings.

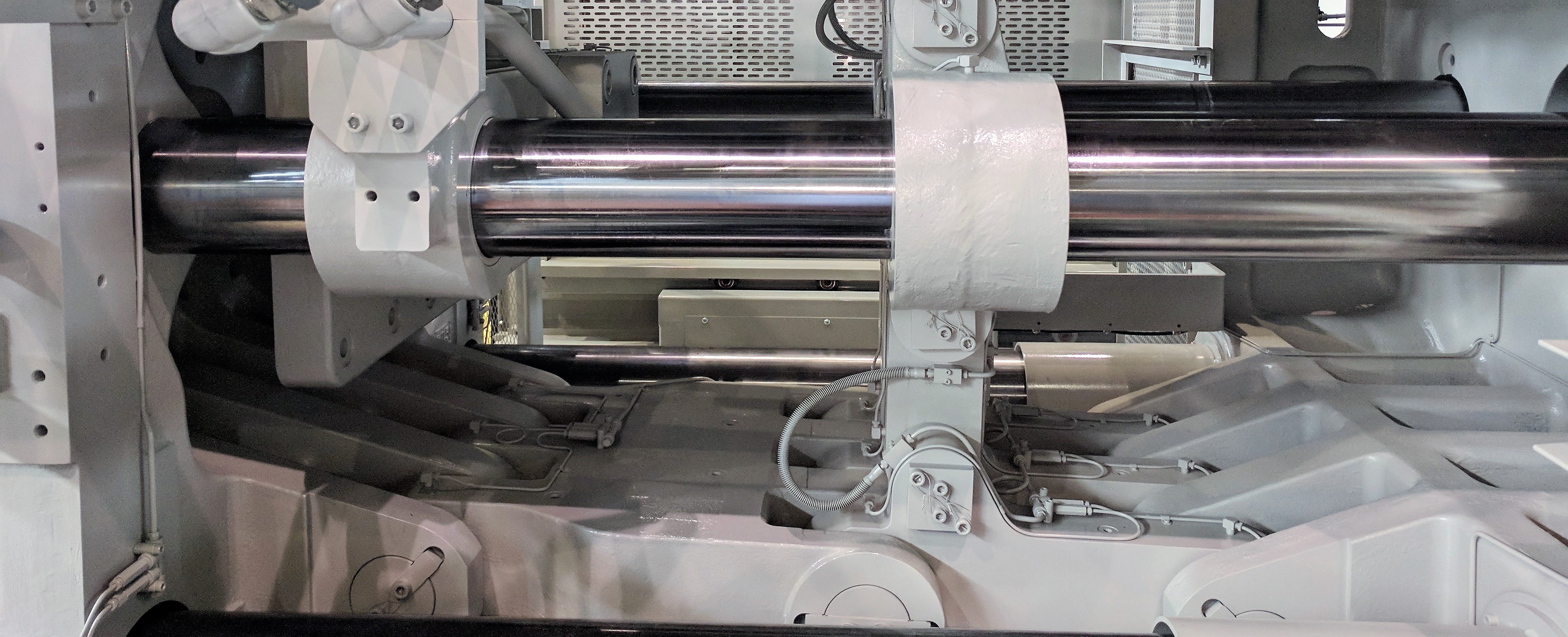

- Die closing: Readying the machine to close and actual closing are two of the most important processes. Shibaura’s electromechanical or conventional full hydraulic control is very good at controlling the closing of the machine and moving the ejector system and cores. This means a more consistent and uniform lock, straining the tie bars uniformly.

- Transfer of metal: Many methods can be used to pour or fill the metal and this process can also cause heat loss, porosity in the casting, or unnecessary turbulence. Shibaura’s die casting ladle function is an integrated part of the control systems’ so it stays in time with the cycle ready to pour when needed.

- Injection process: The injection process is the most important phase of the die casting process. The timing, speed, and pressures used during the injection are all process-related and are not subject to operator changes. Time is not a variable during injection and adding or subtracting even a few seconds can greatly affect end results.

- Die cooling process: While using a die cooling system can reduce time, the cooler can also potentially crack the die if not done properly. Shibaura die-casting machine allows for the cooling of the die to be monitored by the machine control system to help maintain proper dwell time.

- Die opening: During this process, the mechanical core movements should still be considered when deciding the opening speed since too much speed can damage moving elements.

Understand Potential Risks of Reducing Cycle Time

Operating the machine too quickly leaves a higher risk for things to go wrong. Time may look like it is being lost in the cycle time by slowing down a second or two, but in the long run, it will be time (and money) well spent.

Even the slightest changes to the die temperature, metal temperature, shot speed, etc. can hinder the quality of the casting. While you may reduce cycle times you may realize defective castings increase.

Die castings performance may also be affected while working towards reducing cycle times. While it may take a few more seconds to correctly run a cycle, you will be less likely to break die casting pins, or wear and smash slides in the process.

Your Partner in Die Casting

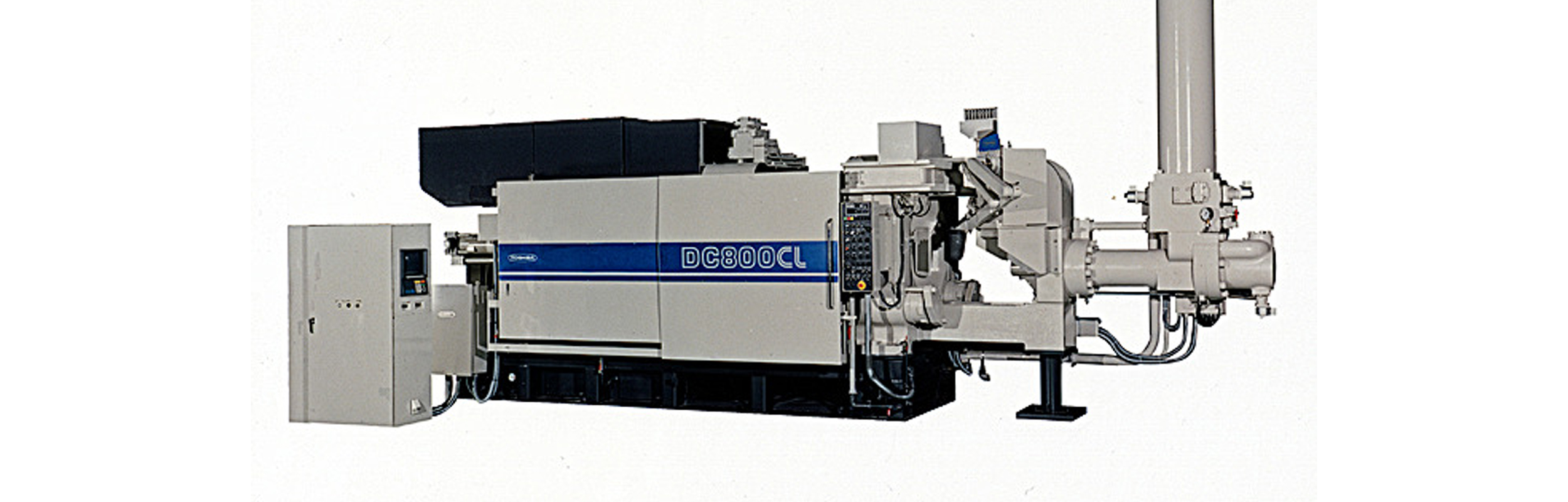

Die casting is a complex process that requires a well-trained operator. Ultimately, understanding and correctly operating the die casting machine will serve more important than working towards cutting seconds off of die cycle time. Shibaura Machine’s die casting machines offer a well-coordinated opening and closing with integrated processes that can save both time and money.

Related Articles View All

Our Commitment to Keep Our Die Casting Customers Up and Running

ELK GROVE VILLAGE, IL, December 16, 2020 When the die casting machine is down costs go up.Avoiding costly downtimes and keeping quality levels high starts with choosing the right machine partner. The right partner will not only provide you with a quality d...

Read moreWorking Together to Make Sure Your Die Casting Equipment is Optimally Operating

ELK GROVE VILLAGE, IL, December 8, 2020 - As a Die Caster, are You Up To Date on the Latest Developments?In an industry that is continually evolving with technology developments, it can be difficult to keep up with the demands of the industry. However, by ...

Read moreShibaura Machine has almost 50 years in the United States

ELK GROVE VILLAGE, IL, June 6, 2020 Shibaura Machine has been manufacturing Die Casting Machines since 1953! Established an office in the United States in 1974! Currently with over 17,000 die-casting machines worldwide! Our team averages almost 25 year...

Read moreShibaura Machine Die Casting Offers Used Machine History Reporting Service

ELK GROVE VILLAGE, IL, July 10, 2020 The purchase of a used machine comes with risks! Help mitigate these risks by requesting a free machine history report. Contact us at dc-MachineFacts@shibaura-machine.com before you consider purchasing a used die casti...

Read moreAvoid damage to your machine caused by extended downtime

ELK GROVE VILLAGE, IL, July 10, 2020 If your die casting machines are not under power for an extended period, You must read the following:The below recommendations will help keep your machines in good running condition and minimize unplanned downtime:KEEP...

Read moreWant to know more about our machines?

Injection Molding Machines

Die Casting Machines

Machine Tools