Automotive Manufacturing Machinery

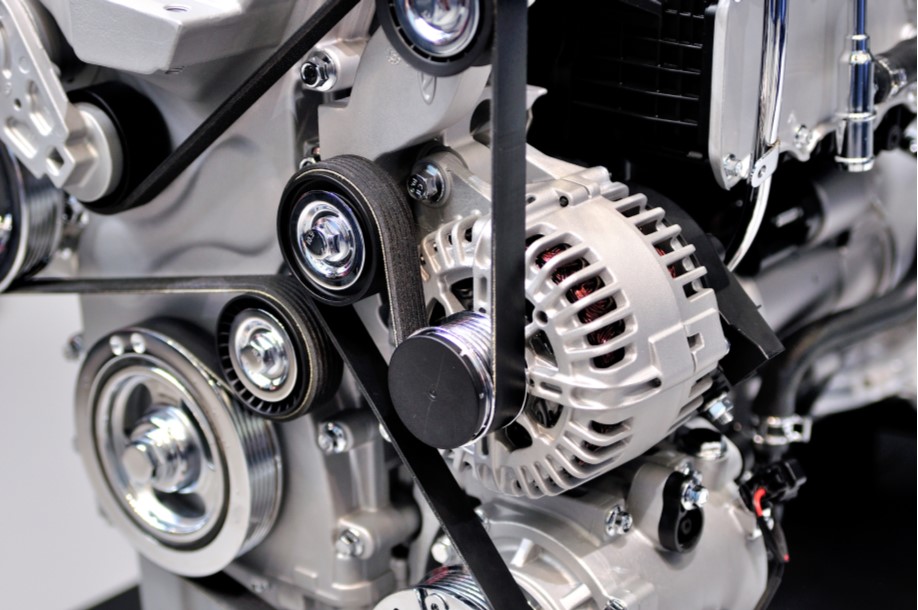

The automotive industry is undergoing tremendous change as consumer preferences in vehicles evolve toward the “CASE” model –Connected, Autonomous, Shared, Electric.

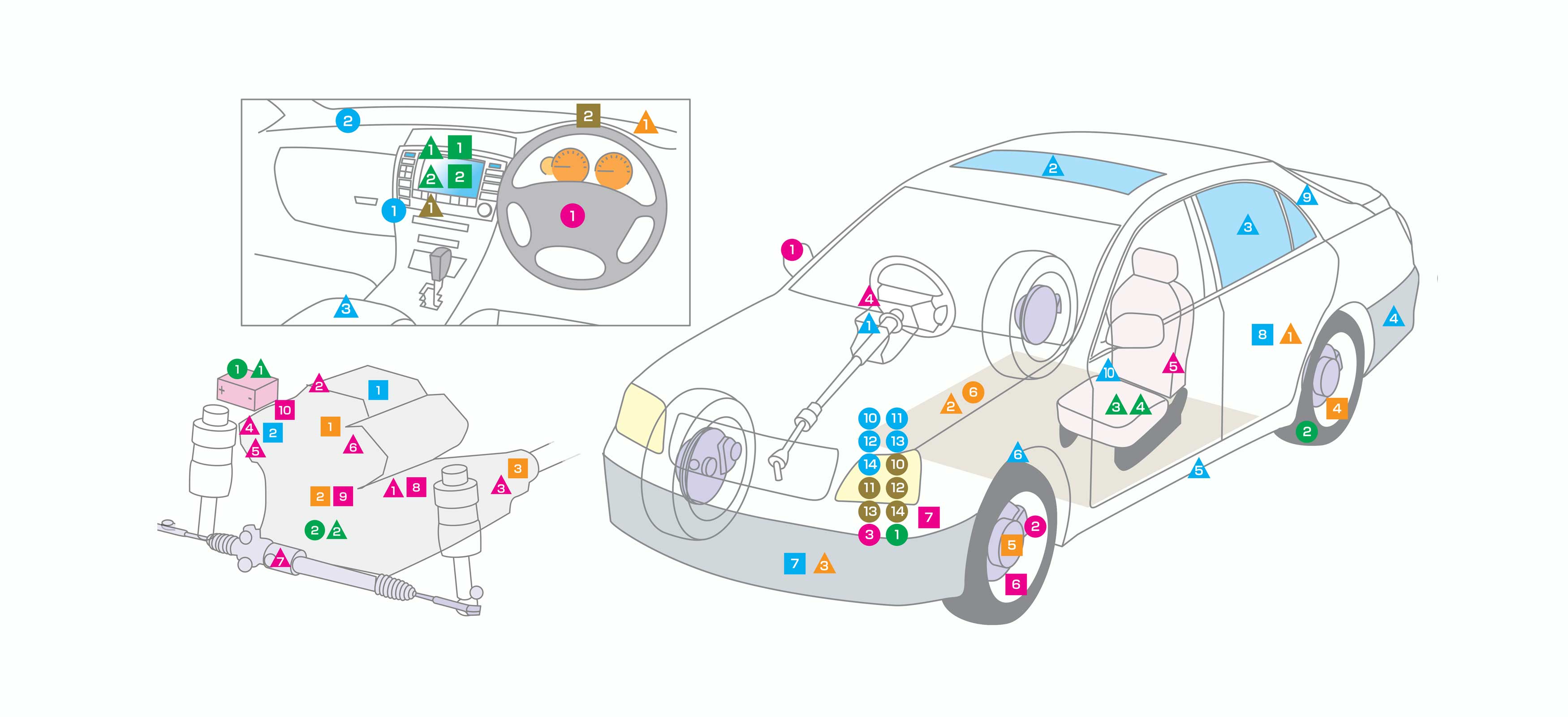

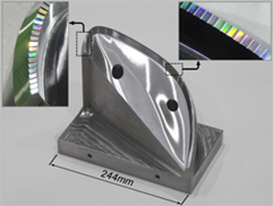

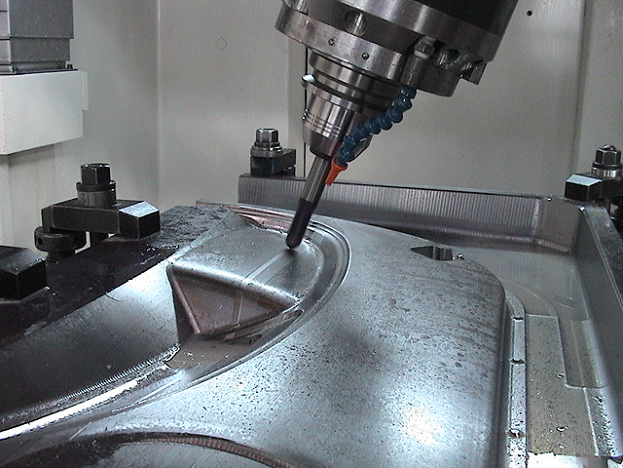

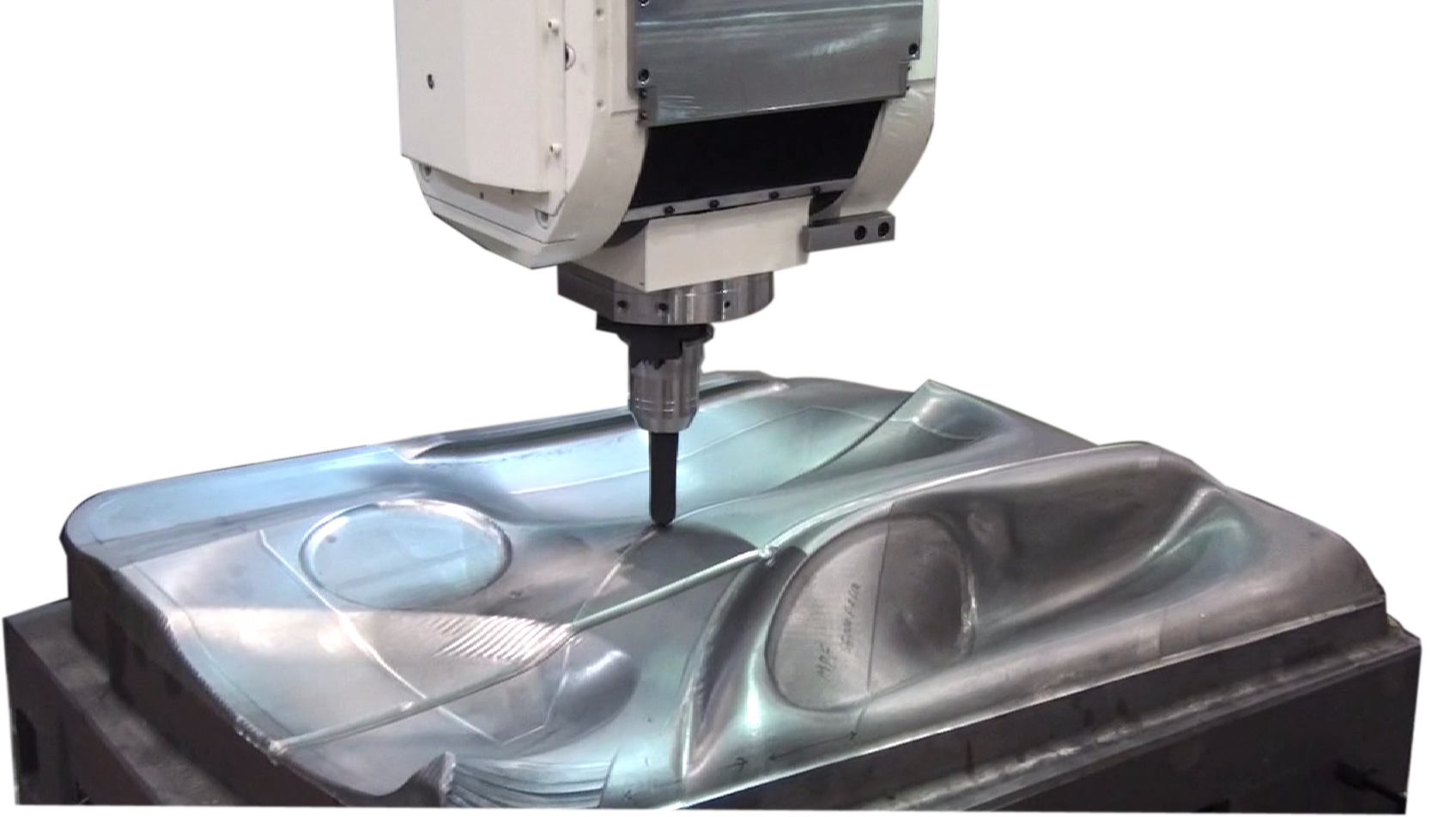

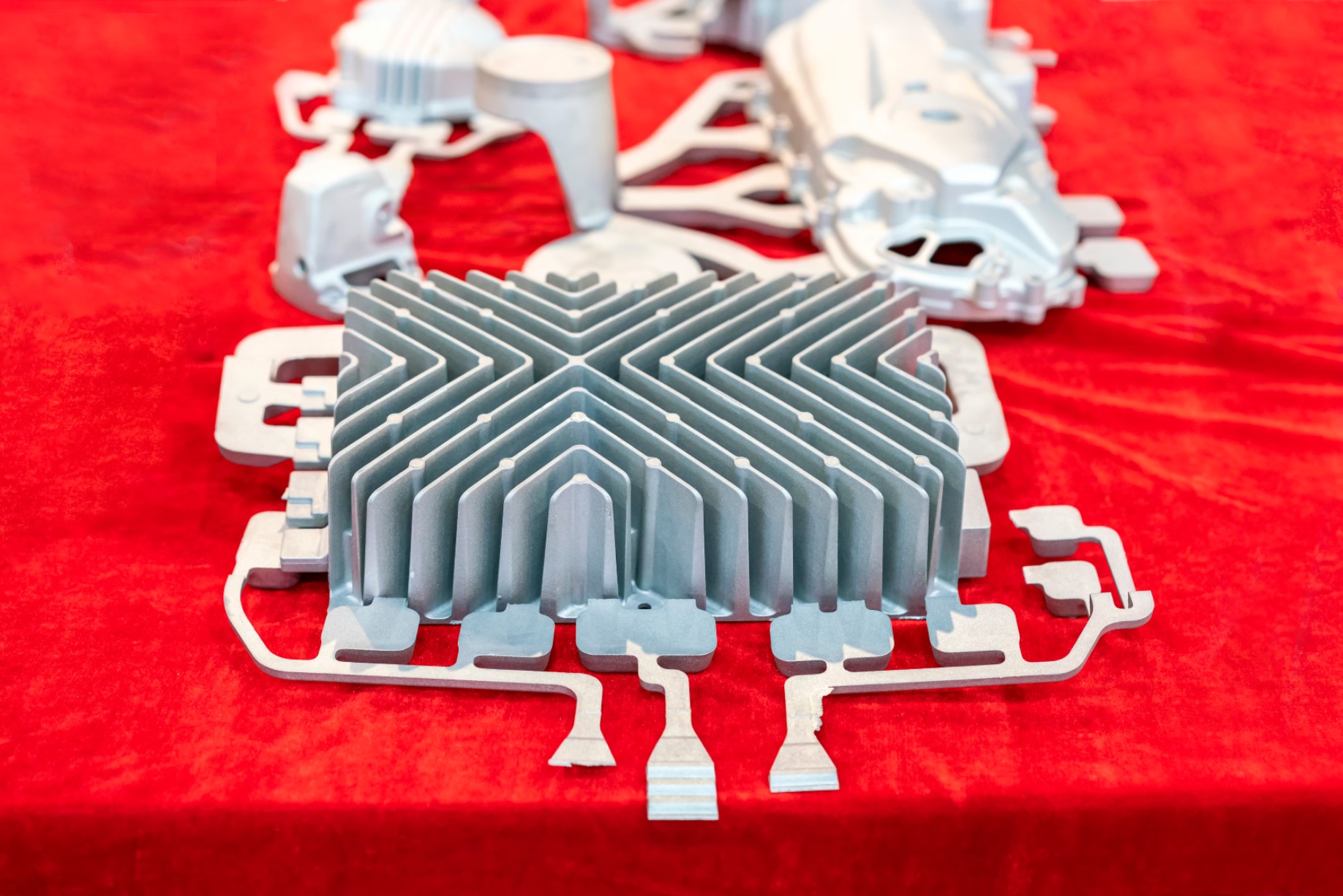

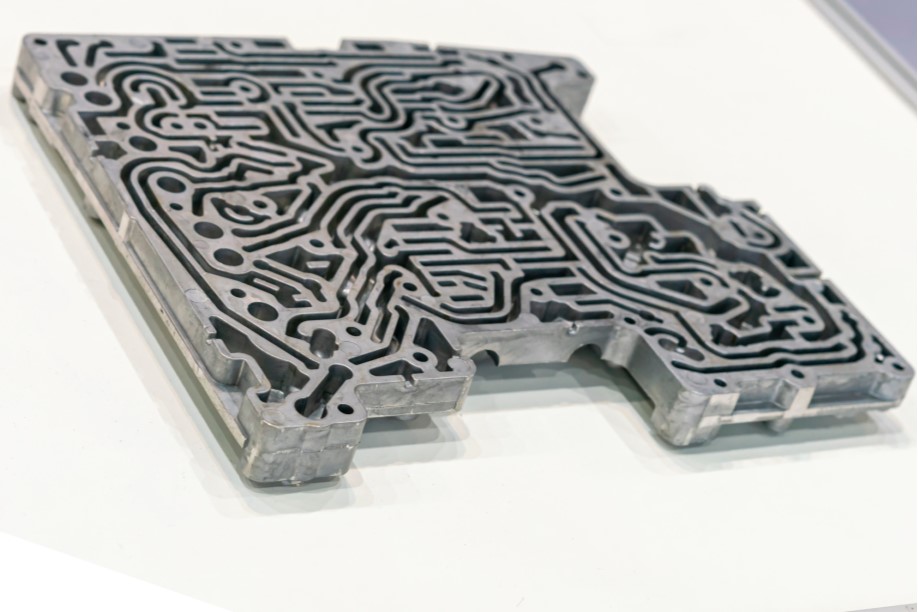

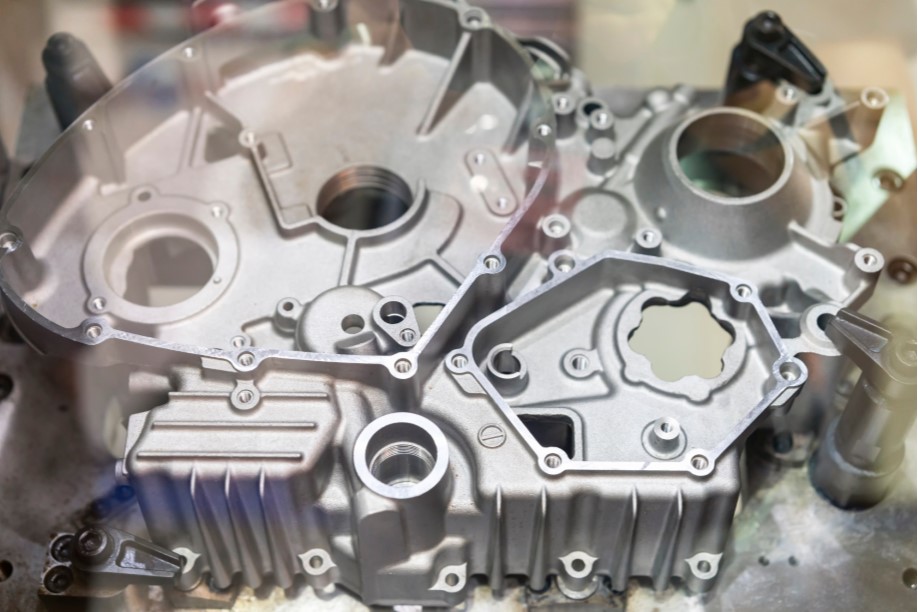

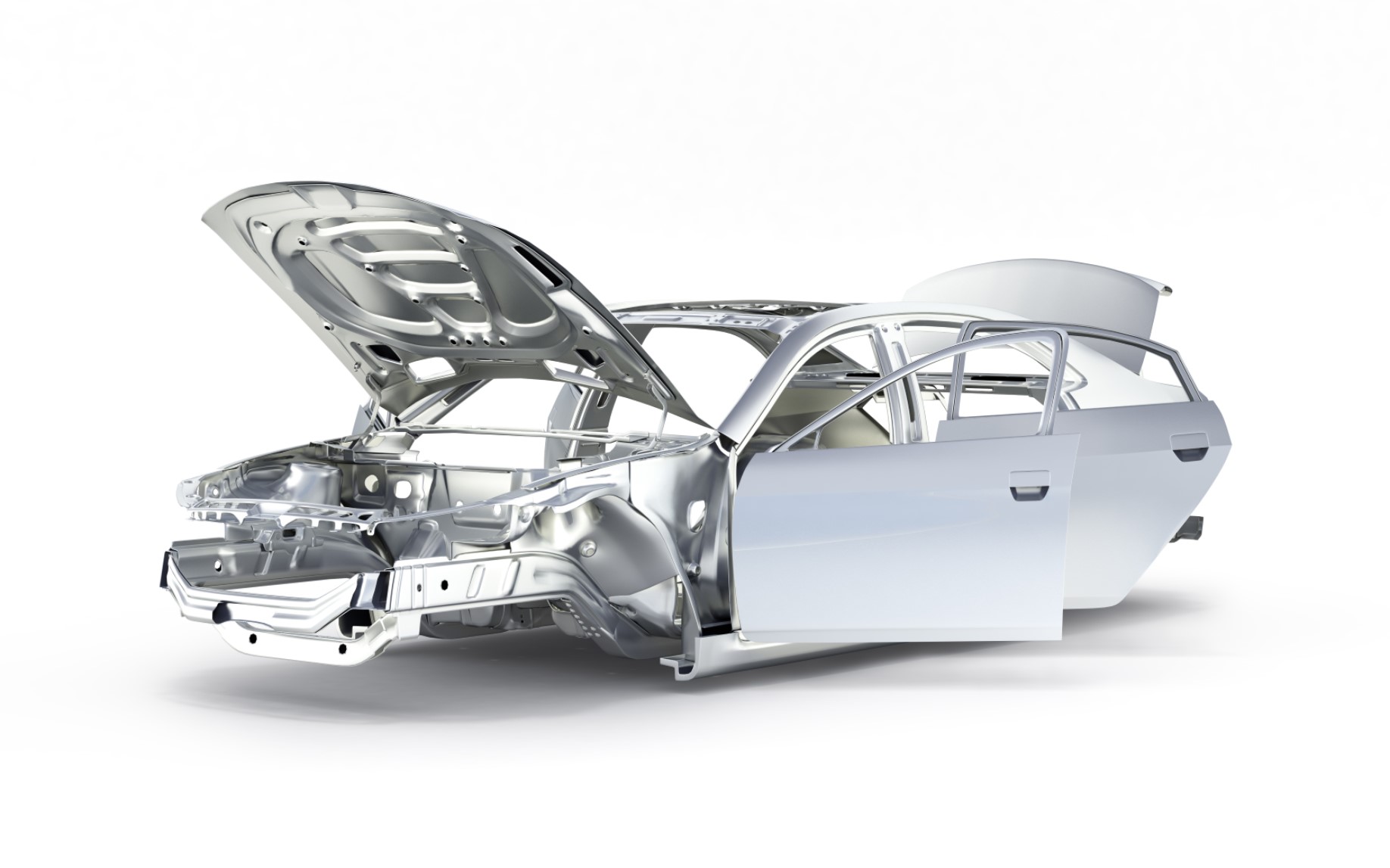

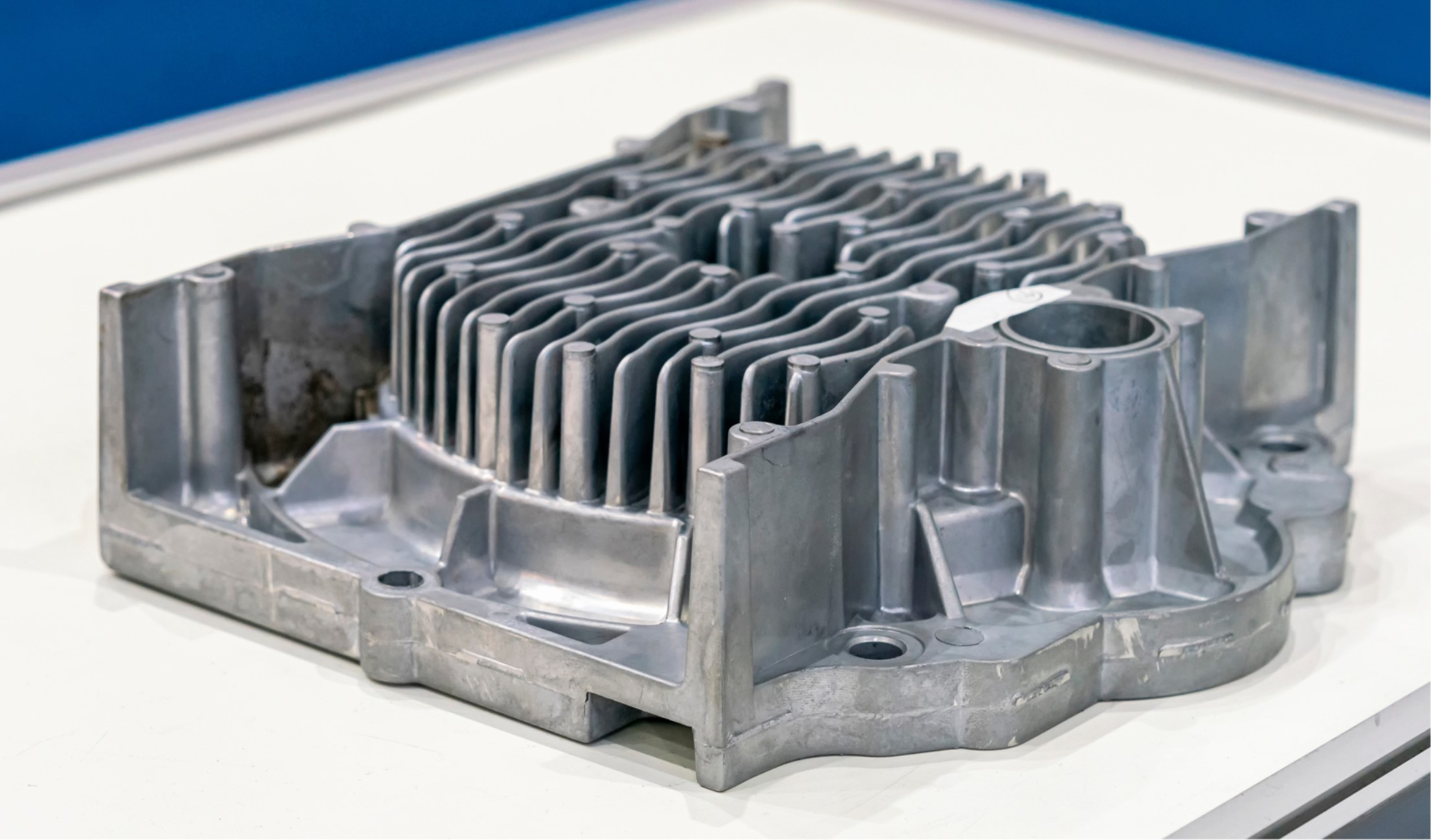

As automotive manufacturers retool to adapt to these changes, Shibaura Machine is in a unique position to support the manufacturing of automotive components associated with these “CASE” technologies. Shibaura Machine is a comprehensive manufacturer of Injection Molding Machines, Die Cast Machines, Machine Tools, Robots, Extruders, and High Precision Glass Molding Machines for the automotive industry. This diverse capability supports the manufacturing of every major automotive component, whether metal, plastic, or glass, interior or exterior, drive-train or trim. We offer state of the art manufacturing equipment and IoT / Industry 4.0 solutions backed up by robust service and parts support.

To learn more about how Shibaura Machine can supply Horizontal Boring Mills, Injection Molding Machines, and Die Casting Machines for the automotive industry, contact us today!

Contact Shibaura Machine today to discuss how we can support your manufacturing needs

Customer Care

- 24/7 Technical Phone Support

- 5 Service Offices and 50 service employees in North America

- 3 Parts Distribution Centers in North America with approximately US$16 Million in parts inventory

- 5 Technical Centers in North America available for customer training and mold trials

- Industry Leading Warranty

Proprietary Shibaura Technology

- Powerful, user-friendly Shibaura controllers with multi-language capability.

- Proprietary Shibaura servo motors and ball screws specifically designed for injection molding, die casting and machining processes. These designs are based on 100+ years of engineering experience.

machiNet IoT+ m / Industry 4.0

- Shibaura machine controllers support OPC-UA communication standards.

- This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP systems.

Customer Testimonials

"The nice thing about a Shibaura Machine is that they never have any downtime"

The Mumford Metal Casting Companies Capabilities:High Pressure Aluminum Die Casting61 HPDC aluminum machines ranging from 400-1,750 TonsHigh Pressure Zinc Die Casting4 hot chamber zinc machines up to 500 TonsMiniature Zinc Die CastingAluminum Gravity (stat...

Exceeding requirements for high-precision, tight-tolerance parts with the help of Shibaura Machine

Performance Gear Systems was founded in 1997 with the mission to be a world leader in the design, engineering, and manufacturing of high precision plastic gears and actuators. Located in Plainfield, IL, this 50,000 square foot cutting-edge facility brings ...

Achieving faster cycle times and a higher level of precision with Shibaura Machine

New Berlin Plastics was founded in 1975. After two company moves in 1976 and 1982, business continued to expand, allowing NBP to transition to a new 100,000 square foot facility in 1998. This facility is located in New Berlin, Wisconsin and serves as the...

Increasing plant efficiency with the help of Shibaura Machine

Founded in 1953, Hoffer Plastics has grown to become an industry leader and innovator in the custom plastic injection molding industry. Located in a 365,000 sq. ft. facility on 24 acres and employing more than 350 people, they produce more than three bill...

FAQ

Is integration with auxiliary equipment available?

Yes, in most cases, auxiliary equipment can be integrated with the primary machinery. Speak to your Shibaura representative for details.

Does Shibaura offer an Industry 4.0 solution?

Shibaura machine controllers support OPC-UA communication standards. This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP systems.

Can Shibaura provide a solution for part traceability?

Yes, part traceability solutions are available. Please speak with your Shibaura Machine representative for details.

Does Shibaura offer 24/7 technical phone support?

Yes, dial (888) 593-1616 #1 for service

Does Shibaura offer financing options?

Yes, our in-house financing arm, TMAC offers a variety of flexible financing solutions. Click here for more information.

Do you offer classroom and/or onsite training?

We offer a variety of training classes. Click here to see our training schedule.