Aerospace

Unbeatable Accuracy, Reliability, and Longevity

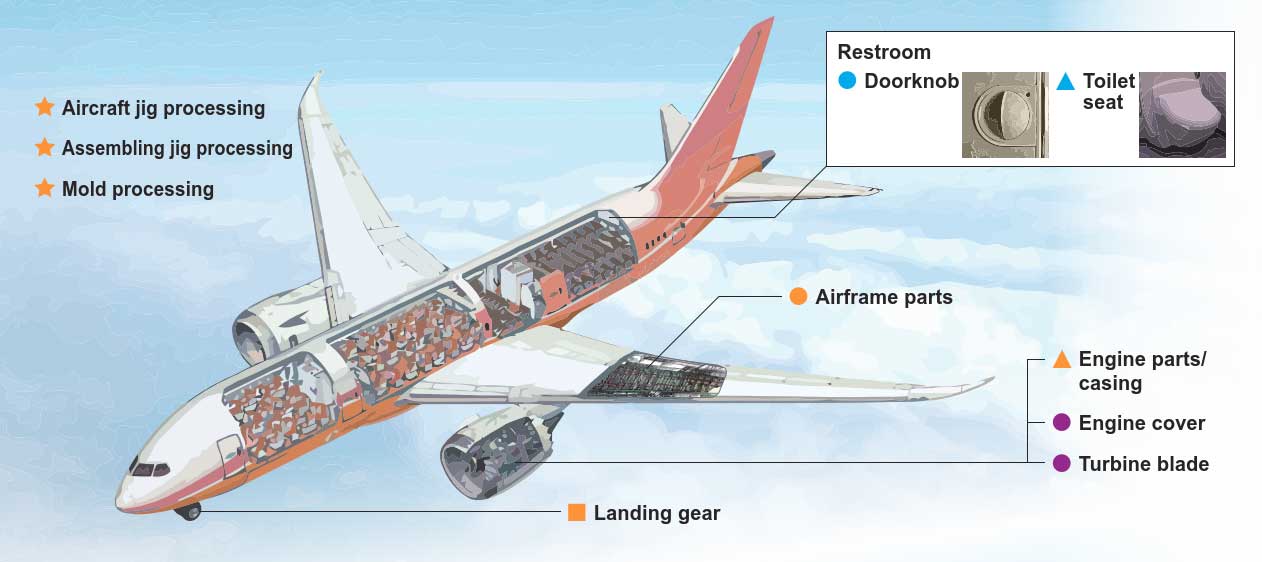

The aerospace industry is one of the most challenging industry sectors. Shibaura Machine is in a unique position to support the manufacture aerospace die casting machines, cnc machine tools, and more. We are one of the few machine builders capable of producing large scale solutions for industry. Our machines are used for applications as large as aircraft wing frames and as small as aircraft interior trim.

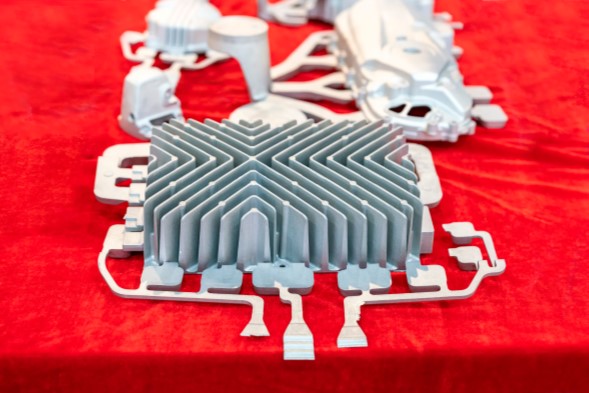

Shibaura Machine is a comprehensive manufacturer of injection molding machines, die cast machines, CNC machine tools, robots, extruders, and high-precision glass molding machines.

This diverse capability supports the manufacture of every major aircraft component for interior, wing frame, jet engine, landing gear and more. The processing of plastics, glass, aluminum, and aircraft grade materials is an area where Shibaura Machine excels.

Shibaura Machine offers state of the art aerospace injection molding machines, cnc machine tools, and IoT/Industry 4.0 solutions backed up by robust service and parts support organizations.

Shibaura Machine designs all aerospace die casting machines to ensure maximum productivity, minimum downtime, and long-lasting machine life. This provides Shibaura Machine customers with more economical cost of ownership in the long term.

Contact Shibaura Machine today to discuss how we can support your aerospace manufacturing needs

Customer Care

- 24/7 Technical Phone Support

- 5 Service Offices and 50 service employees in North America

- 3 Parts Distribution Centers in North America with approximately US$16 Million in parts inventory

- 5 Technical Centers in North America available for customer training and mold trials

- Industry Leading Warranty

Proprietary Shibaura Technology

- Powerful, user-friendly Shibaura controllers with multi-language capability.

- Proprietary Shibaura servo motors and ball screws specifically designed for injection molding, die casting and machining processes. These designs are based on 100+ years of engineering experience.

machiNet IoT+ m / Industry 4.0

- Shibaura machine controllers support OPC-UA communication standards.

- This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP systems.

" Boeing has won in the marketplace for 100 years because of innovation, and we need to continue to invest in innovation for the future"

Dennis Muilenburg

Former president and Chief Executive Officer of The Boeing Company

Customer Testimonials

"The nice thing about a Shibaura Machine is that they never have any downtime"

The Mumford Metal Casting Companies Capabilities:High Pressure Aluminum Die Casting61 HPDC aluminum machines ranging from 400-1,750 TonsHigh Pressure Zinc Die Casting4 hot chamber zinc machines up to 500 TonsMiniature Zinc Die CastingAluminum Gravity (stat...

There are various manufacturers in the market. We purchased Shibaura Machine for dependability and accuracy.

"The majority of our work is in the machine tool and plastic injection industries. When we were purchasing a new machine, we were looking for a dependable and accurate machine. We considered various manufacturers in the market. We went to Japan to see the ...

"We wanted Heavy duty machining without losing its capability and accuracy."

FRISA is one of the world´s leading forged steel manufacturer; We want to be the best option for each of our customers, offering high-value forging solutions; for the Aerospace industry, we´ve been providing seamless rolled rings in nickel and titanium all...

FAQ

Is integration with auxiliary equipment available?

Yes, in most cases, auxiliary equipment can be integrated with the primary machinery. Speak to your Shibaura representative for details.

Does Shibaura offer an Industry 4.0 solution?

Shibaura machine controllers support OPC-UA communication standards. This capability along with our machiNet IoT+m platform allows machine and process data to be remotely monitored and shared with plant MES and ERP systems.

Can Shibaura provide a solution for part traceability?

Yes, part traceability solutions are available. Please speak with your Shibaura Machine representative for details.

Does Shibaura offer 24/7 technical phone support?

Yes, dial (888) 593-1616 #1 for service

Does Shibaura offer financing options?

Yes, our in-house financing arm, TMAC offers a variety of flexible financing solutions. Click here for more information.

Do you offer classroom and/or onsite training?

We offer a variety of training classes. Click here to see our training schedule.